Induction Scanners By Radyne

What is an Induction Scanner?

An induction scanner is an extremely versatile machine that uses induction heating technology to perform heat-treating processes along the length of a part. You can think of these like kind of like the scanner on a copy machine except instead of scanning a picture you are scanning heat across a part. Induction scanners are most commonly used for progressive hardening operations but can be used for many other purposes including annealing, shrink fitting, and automated brazing. Scanners are advantageous because they offer unmatched control over every aspect of the process. Maintaining the proper power level, frequency, scan speed, and rotation as well as quench flow, pressure, and polymer concentration are all crucial to producing a consistently hardened part. Induction scanners from Radyne offer precise control over each of these aspects leading to highly consistent hardness profiles and in turn less waste.

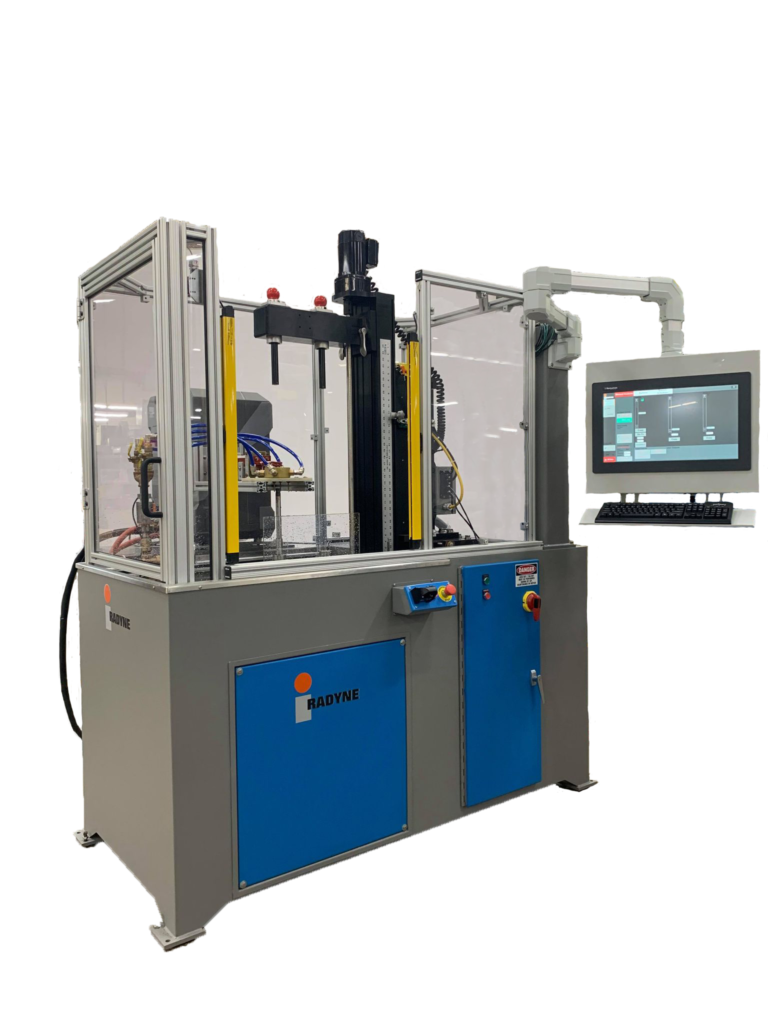

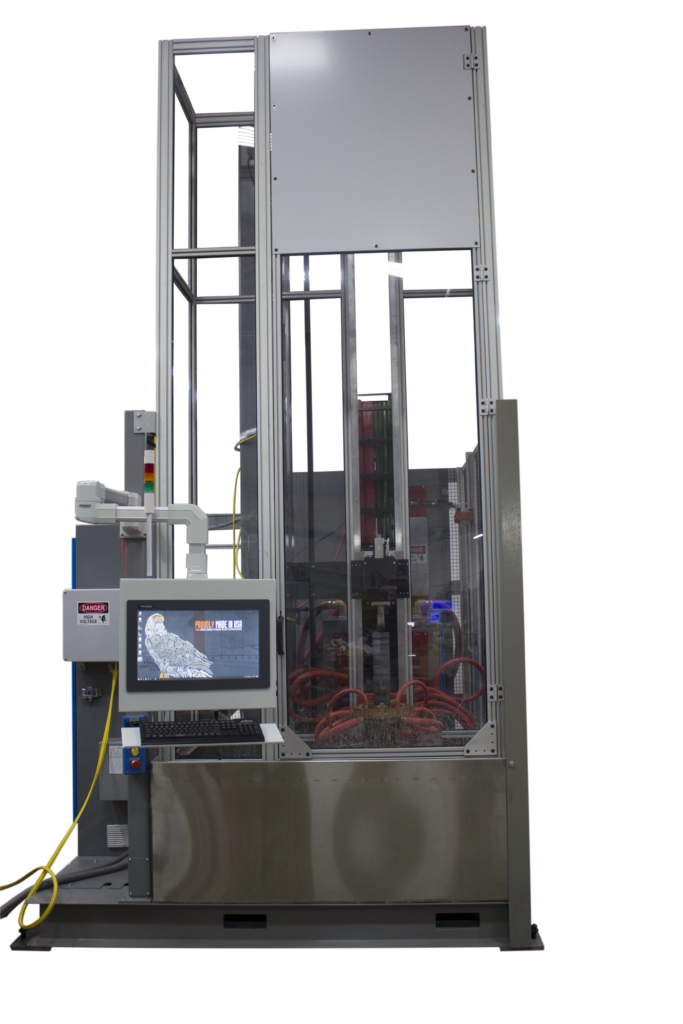

ScanMaster™ Induction Scanners

ScanMaster™ is the name of Radyne’s flagship induction scanner lineup. ScanMaster™ induction scanners are designed to accommodate a variety of heat treating processes for a wide range of part weights, lengths, and shapes. Radyne ScanMaster™ systems can handle parts ranging from under an ounce and shorter than an inch to over 5000lbs and 120 inches in length.

A typical ScanMaster™ induction scanner includes the scanner base, scanning tower, power supply, Induction coil, standard guarding, safety light curtains, ScanMaster™ (Motus) controls package, and configurable water & quench cooling systems.

ScanMaster™ induction scanners are modularly designed so that components can be modified or swapped out as production needs change.

Radyne currently offers four different versions of our ScanMaster™ System. Our smallest Is the ScanMaster™ 28 which can accommodate parts up to 28 inches long and up to 75lbs. Our Largest is the ScanMaster™ 120 boasting an impressive 120-inch scan length and 5,000 lbs weight capacity. Browse our ScanMaster™ systems below and see why Radyne scanners are trusted by manufacturers around the world.

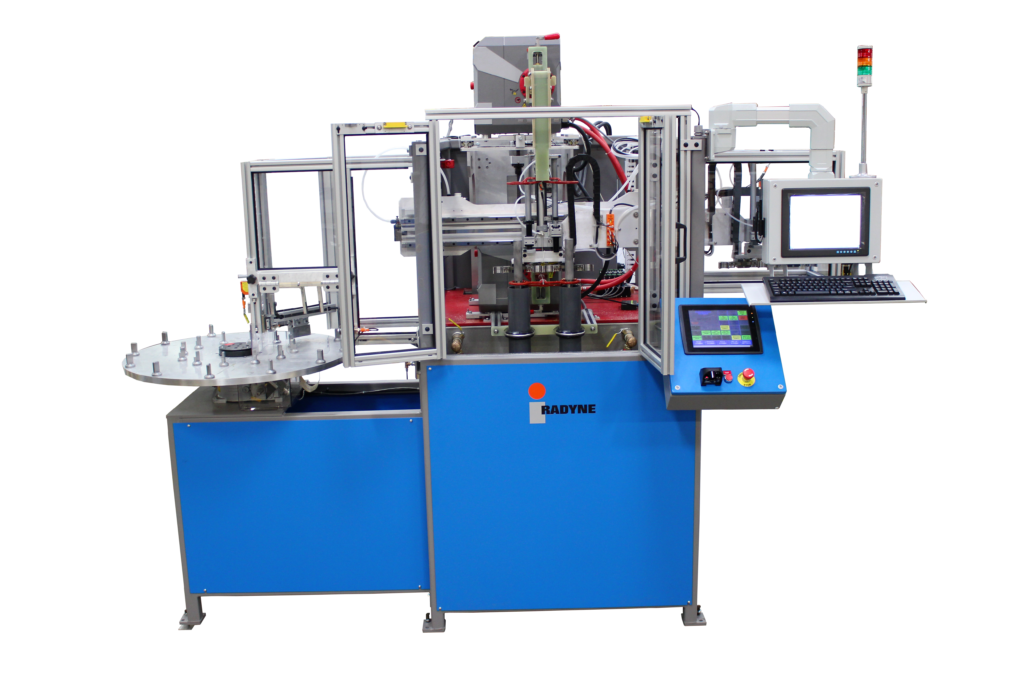

FlexScan™ Pop-Up Scanners

FlexScan™ pop-up scanners are similar to our line of ScanMaster™ systems with the main difference being that FlexScan™ trades a scanning tower for one or multiple spindles that extend up from the bottom of the quench basin. Pop-up scanners are advantageous for manufacturers that need a cost-effective system with a compact footprint.

The operator’s interface features a full-color HMI display with embedded controls. The ScanMaster™ (Motus) controls package can optionally be fitted to these systems as well for increased controllability of your process.

FlexScan™ 12 XL

12-inch scan length

75 lbs maximum payload

Larger quench basin

Pictured with Pick-n-Place material handling (optional)

Robotics and Material Handling Integration

Both ScanMaster™ and FlexScan™ systems are designed to integrate seamlessly with robotics and other material handling systems.

Like What You See?

Fill out the contact form below and one of our representatives will contact you shortly