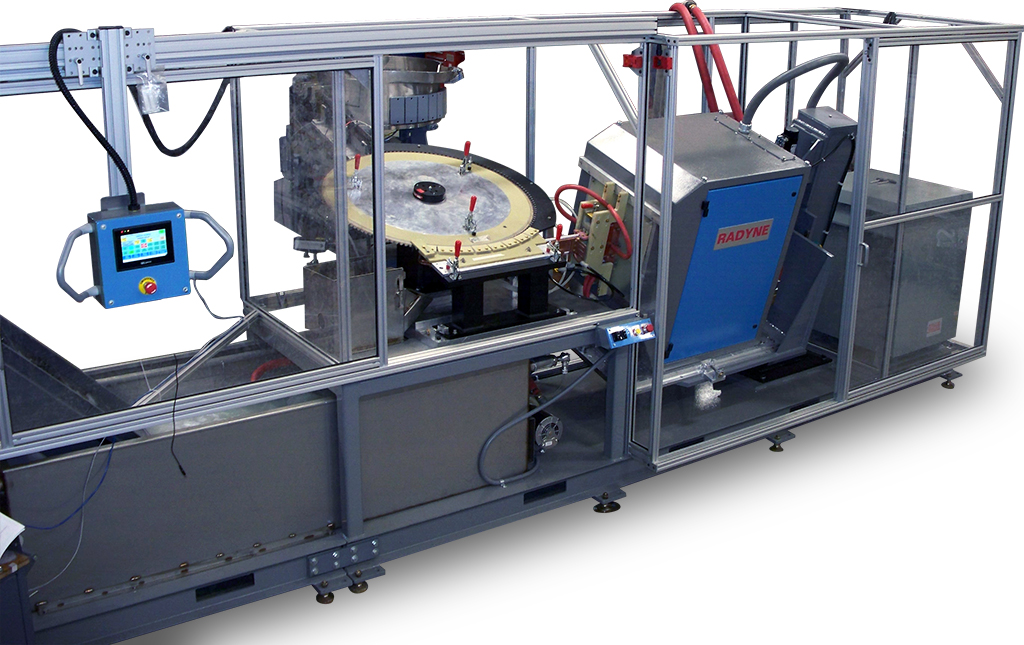

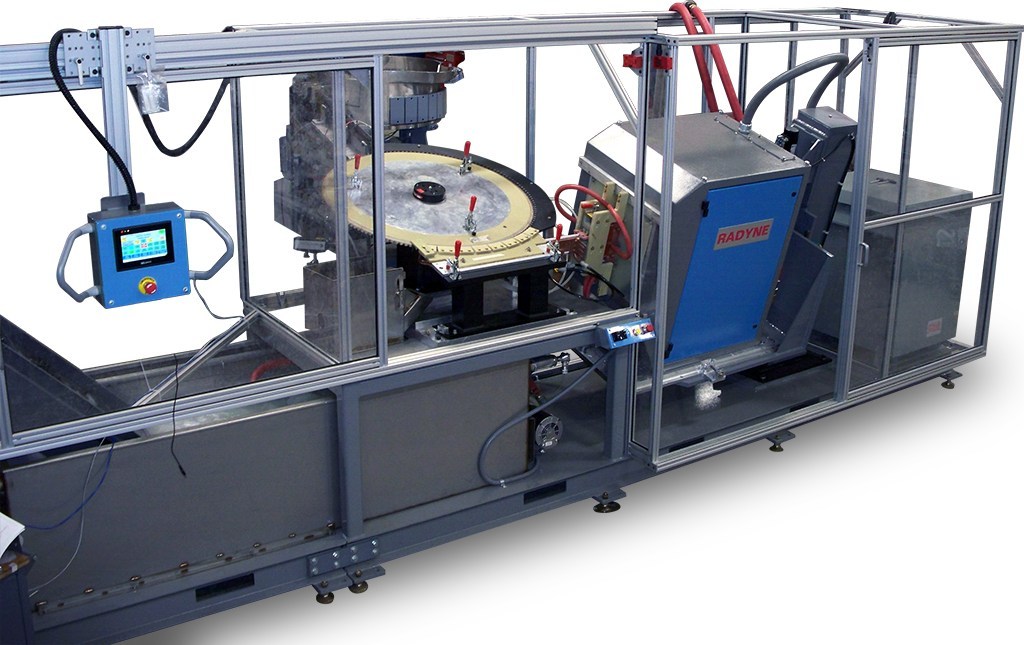

Fastener Heat Treating System

Radyne’s Fastener Heat Treating System delivers uniformity, consistency and increased controllability that results in superior quality fasteners. It is adjustable for a wide range of fastener/bolt lengths and diameters, and is capable of production rates of up to 400 fasteners per minute.

This fully automatic system includes vibratory bowl feeder, rotary part indexing, Induction Heating with recipe based Servo Controlled Positioning, a range of induction heating coils to meet the heating pattern requirements of various common fasteners, integrated quench, conveyor unload, Color Touch Screen Control Panel and a chart recording system.

Fastener Heat Treating Systems Features

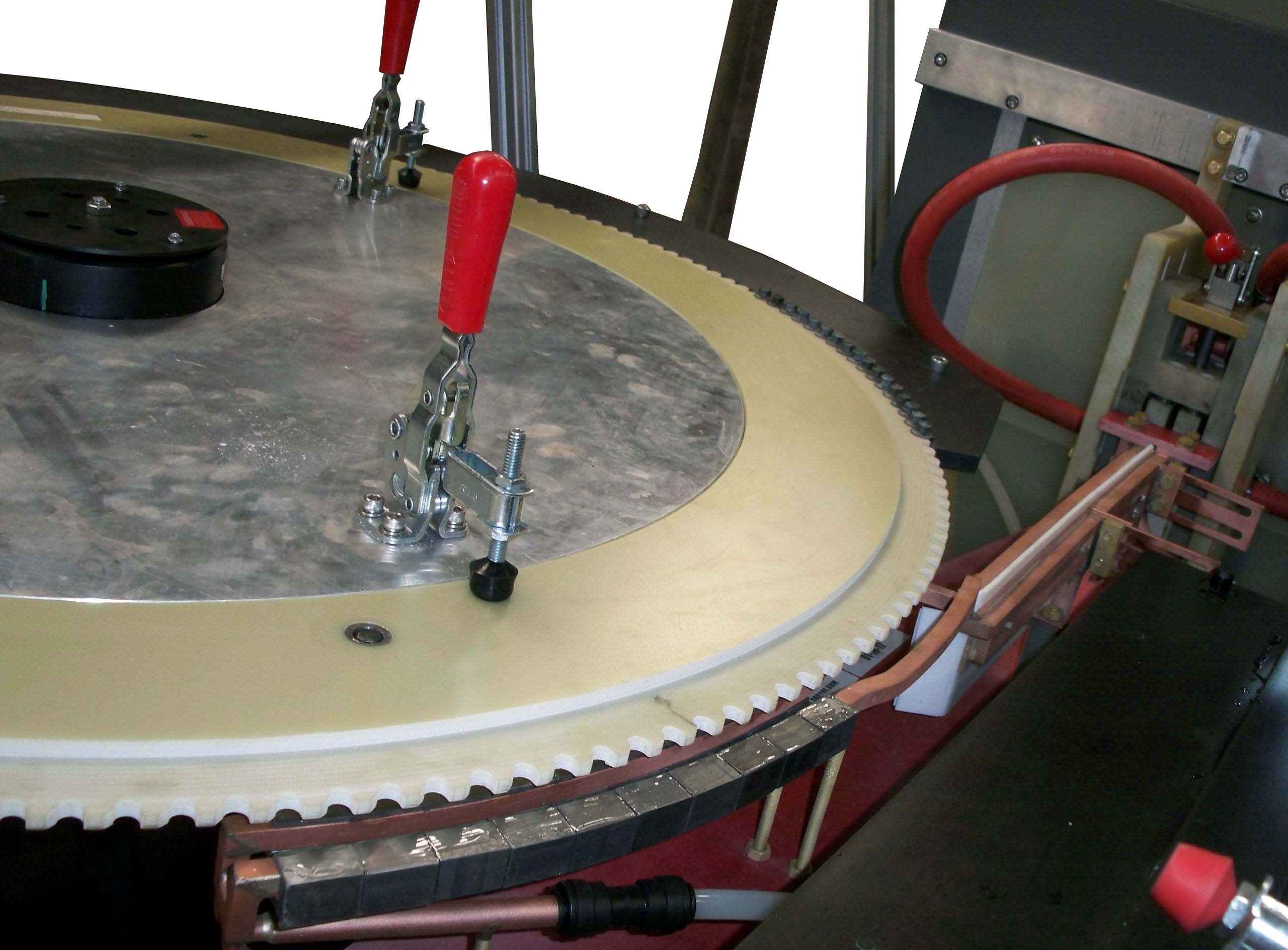

Induction Coil & Quench Assemblies

Designed and manufactured from Oxygen Free High Conductivity (OFHC) water cooled copper material for the utmost efficiency of power to part. The unique proprietary coil includes flux concentrating material to prevent stray heating of surrounding equipment. The quench assembly is manufactured from nonferrous material, and has manual flow control valves for utmost quench control. After spray quenching, parts are stripped from the traverse assembly and dunk quenched into the tank for final cooling to ambient.

Rotary Bolt Heat Treat & Traverse Fixture

Mounted to a ruggedly welded steel frame, the rotary dial tooling is designed to accept bolt fasteners from the inline vibratory feeder. The adjustable speed rotary table contains advanced safety features to prevent damage and meltdown. The tooling is designed with a quick change feature to ensure all tooling can be changed for a different part size in less than 15 minutes. The system is controlled through a controls package and HMI for part set-up and part storage of different programs. Through this HMI, the power source coil “Z” adjustment can also be stored and adjusted for different bolt lengths. This unit includes four sizes of tooling required for the rotary heat treat fixture and the traverse tooling: M6, M8, M10 & M12. Designed and manufactured from nonmetallic material, the tooling can withstand the temperature of the fasteners being heated.

Closed Loop Water Cooling Tower

The water cooling tower is comprised of two main sections; an air cooled heat exchanger and a closed loop pumping section. The heat transfer coil is fabricated from seamless copper tubing with mechanically expanded full fin collars for permanent fin-tube contact. Housing for the air-cooler is constructed from heavy gauge galvanized steel, designed to provide maximum casing rigidity as well as high corrosion protection.

Vibratory Bowl Feeder

Designed and manufactured for M6, M8, M10 & M12 bolts. An inline vibratory feed system interfaces the rotary heat treat fixture to orientate and deliver the bolts to the table tooling.

- Bowl feeder and dial moves parts into the induction coil

- Heated parts fall into quench tank & Rear exit conveyor

- 200 to 400 fastener/bolts per minute

- Adjustable for multiple bolt lengths

- Uniform concentric pattern

- Decreased energy consumption

- Case hardening instead of through hardening for increased part strength

- Quick tooling changeover

- Conserves floor space

Fastener Heat Treating Systems Accessories

Quick Coil Disconnect Function

The coil Quick Disconnect is designed to allow quick changeover between coils for maximum uptime and flexibility. Simple to install, the assembly bolts directly to the power source output and allows coils to be easily changed without the use of tools or attachment of water connections.

Solid construction and a heat-resistant glass fiber composite alignment plate assure correct and consistent positioning of the coil relative to the component position. The center locking lever and optional ratcheting handle allow the operator to loosen or tighten the tooling for fixed placement of your coil assembly

Features

| Multiple Inductor & Quench Assembly Options |

| Rotary Bolt Heat Treat & Traverse Fixture |

| Closed Loop Water Cooling Tower |

| Vibratory Bowl Feeder |

| 200 to 400 fastener/bolts per minute |

| Adjustable for multiple bolt lengths |

| Uniform concentric pattern |

| Decreased energy consumption |

| Quick tooling changeover |

| Small footprint conserves floor space |

Tech Specs

| Bolt Diameter: | M6, M8, M10 & M12 headed 4037 steel fasteners |

| Bolt Length: | 12 mm – 101.6 mm [.05 – 4.0 in.] |

| Hardness: | 52 – 55 HRC after induction hardening as quenched for the first 3 threads |

| Production Rate: | 200 – 400 per minute |

| Frequency Range: | 200-400 kHz |

| Maximum Voltage: | 360 Vrms |

| Maximum Power: | 100 kW |

| Minimum Power Factor: | 0.85 |

| Duty Cycle: | 100% |

- Digital meters for monitoring voltage, current, frequency and power

- Programmable Display Interface

- 440 – 480 V Three Phase

- Water Cooled