Advanced Induction Concepts

Advanced Induction Heating Concepts

A working understanding of induction heating that extends beyond the basics is essential to getting the most out of your induction heating system. Learning the relationship between advanced induction heating concepts and how effective heating leverages induction theory allows for informed operation.

Skin Effect

Skin effect results from the tendency of the current density to be the greatest at the surface.

The overall effect is that a relatively heavy current is induced at the very surface of the workpiece, but the current density, field strength and power all decrease the deeper we go into the material. It stands to reason that the current at the center of the bar is zero, since the current on each side of the center is going in opposite directions.

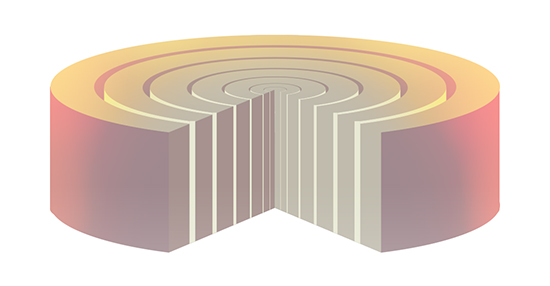

When considering this effect, it is useful to consider the eddy currents in a work piece as thin sleeves telescoped over each other. The total current of a work piece is obtained by taking the combined effect of all the individual currents in the individual sleeves. When a current flows in one sleeve, it inevitably has a magnetic effect upon the strength of the field through it, which automatically means that the voltage induced in lower sleeves is less. Deeper currents are smaller, and they lag in phase, but they are all of the same frequency.

The effects of the skin effect becomes more pronounced by increasing the frequency. Conversely, the effect can be reduced by lowering the frequency, at the cost of efficiency. However, even with very low frequencies, if the work piece is large enough, there will be sufficient skin effect for efficient induction heating. In all cases with induction heating the current induced near the surface is larger than the current induced near the center of a solid conductive part.

Skin effect depends upon more than just the frequency and the size of the workpiece. It also depends upon the temperature and magnetic and electric properties of the material from which the work piece is made. These properties can change with temperature and magnetic field intensity. Skin effect is more pronounced when the resistivity is low or magnetic permeability is high.

Frequency

Induction heated products do not rely on convection or radiation for the delivery of heat to the product surface. Instead, heat is generated on the surface of the product by the flow of current. The heat from the product surface is then transferred through the product with thermal conduction. The depth to which heat is generated directly using the induced current depends on something called the electrical reference depth.

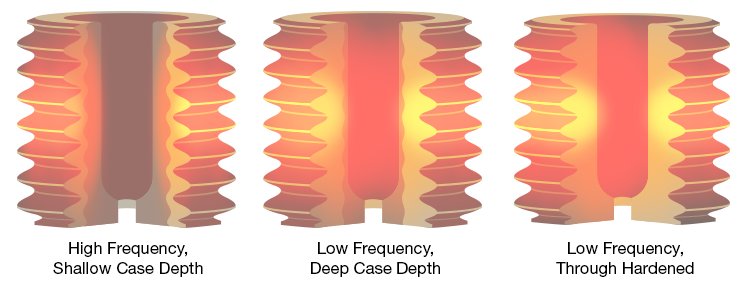

The electrical reference depth depends greatly on the frequency of the alternating current, flowing through the work piece. Higher frequency current will result in a shallower electrical reference depth and a lower frequency current will result in a deeper electrical reference depth. This depth also depends on the electrical and magnetic properties of the work piece.

This mechanic is fundamental to achieving specific heating profiles in case hardening, as shown above. In processes requiring a thinner depth in case hardening, higher frequency suits the application. Radyne takes advantage of these physical and electrical phenomena to customize heating solutions for specific products and applications. The careful control of power, frequency, and coil geometry allow Radyne to design equipment with high levels of process control and reliability, regardless of the application.

Further Reading

For even more induction heating resources, Radyne supplies a few resources for your convenience, allowing you to leverage induction theory for informed operation: including posters for reference of common laboratory and shop floor charts, and reference books on the topic of the basics of induction heating. Feel free to look at our power units, the TFD, and our Versapower-Xtreme.