Annealing Equipment

Annealing is a common practice across numerous industries. Radyne Is experienced in producing high-quality, cutting-edge equipment for annealing tailored to fit the needs of diverse industries.

Ammunition Manufacturing

The ammunition industry commonly uses specialized annealing equipment to produce bullet casings with favorable metallurgical properties. When Producing bullet casings, the brass begins as a flat sheet punched into short and stout cups. These Cups then undergo multiple drawing stages that form the body and neck of the casings. Between each drawing and forming stage, the casing must be annealed to prevent cracking. These Casing Annealing Systems need to be highly accurate to produce a consistent annealing profile. Failure to anneal a casing properly could lead to sub-par quality ammunition. Radyne is highly experienced in providing systems to anneal casings during every stage from cup annealing to the final neck taper annealing. Browse our selection of casing annealing equipment below, or click here to learn more about induction in the ammunition industry.

Radyne Casing Annealing System

The Radyne Casing Annealing System or CAS is designed for annealing casings during the neck taper stages. It comes in two sizes for medium or high throughput. This system utilizes a rotary table with an automatic collator and feeder system to facilitate easy loading and continuous operation. Precision induction coils and cutting-edge control firmware ensure a highly consistent annealing profile. Click the photograph to learn more about the Radyne CAS.

FlexScan Pop-up Scanners

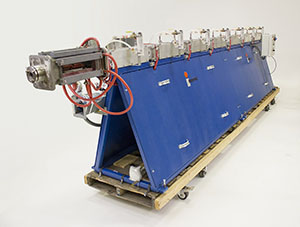

FlexScan pop-up induction scanners can be used to anneal large-caliber ammunition casings used in artillery and heavy weapons. The system has the ability to run two-up and is able to produce extremely precise annealing profiles by scanning the neck and body of the casing. Click the photograph to learn more about FlexScan Pop-up Scanners.

Wire Manufacturing

The wire and cable industry commonly utilizes induction annealing equipment to anneal wires in between and after the drawing stages to increase ductility and improve electrical conductivity. Induction technology is especially desirable for the annealing of wire because it is highly accurate and allows for annealing in a controlled atmosphere. Browse our selection of induction wire annealing equipment below, or click here to learn more about the wire manufacturing industry.

Bright Annealing Wire Line

The Radyne Bright Annealing Wire line is a turn-key system for annealing wire in a controlled atmosphere. It fits directly in line with today’s high-speed drawing and rolling lines. making them the preferred choice for lean, agile manufacturing.

Tube & Pipe Manufacturing

The production of tubes and pipes often requires annealing during or after forming or drawing. Both seamed and seamless pipes and tubes can require annealing to ensure the product has consistent and desirable metallurgical properties. Click here to learn more about tube and pipe manufacturing.

Also See: Weld stress relieving.

Dull Annealing Tube Line

The Radyne Dull Annealing Tube Line is a turn-key inline annealing system designed to anneal small diameter pipes and tubes in the open air. It fits directly in line with high-speed drawing and rolling equipment making it an ideal drop-in system for existing lines.

Bright Annealing Tube Line

The Radyne Bright Annealing Tube Line is the ideal system for annealing small diameter tubes and pipes in a controlled atmosphere. The system fits directly in line with high-speed drawing and rolling equipment and can be optioned with gas quench to eliminate post-annealing cleaning completely.