What Are The Advantages of Induction Brazing?

March 5th, 2021

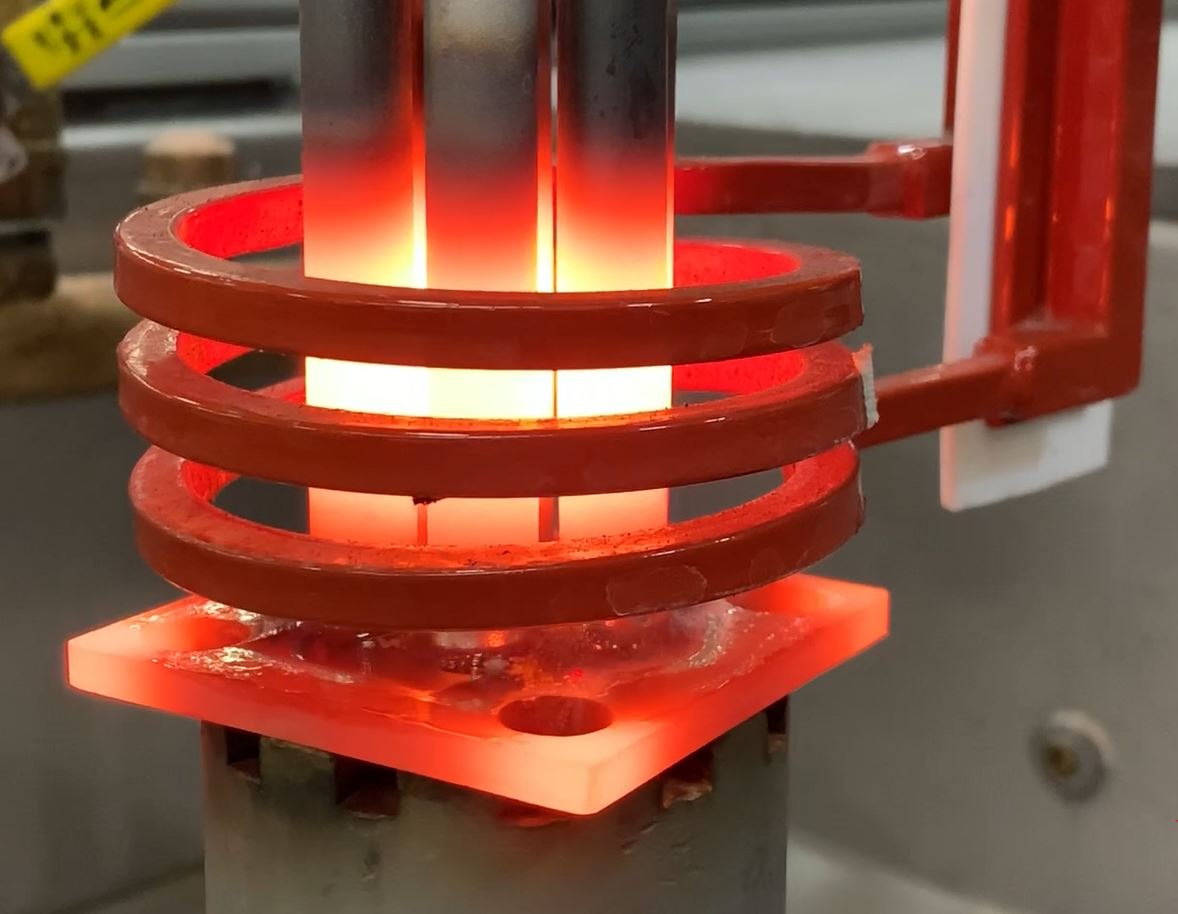

Induction brazing has many advantages over the other common heating methods prevalent today. Reasons to consider using induction heat include:

- Quick, rapid heating

- Controlled, precise heat control

- Selective (localized) heat

- Production line adaptability and integration

- Improved fixture life and simplicity

- Repeatable, reliable brazed joints

- Improved safety

Quick changeover, repeatability make induction brazing a leading candidate in manufacturing environments that embrace operational excellence and lean, six sigma.

Quick, rapid heating

Compared to torch brazing and furnace brazing, normal induction heating cycle times are substantially faster. A properly designed induction heating coil allows the area to be brazed to heat quickly. The cycle time using induction is significantly lower when compared to furnace brazing. Furnace brazing requires the entire part assembly to be brought up to brazing temperature while brazing with induction requires only the joint interface to be heated, allowing the braze alloy to flow and capillary into the joint interface. Typical induction brazing is conducted in air, yet induction can be configured to be done in a controlled atmosphere with a Radyne controlled atmosphere induction brazing systems such as nitrogen or argon, reducing the amount of flux needed and often eliminating the need to flux components. An induction brazing system is adaptable for vacuum brazing in environments where a vacuum environment is necessary.

Controlled, precise heat control

An advantage of induction brazing vs. torch brazing is the ability to control the process temperature. With the VersaPower®-Xtreme™ induction power supply, the unit is able to ramp up from 0-100% of rated power in as low as 50 milliseconds, delivering uniform heating, precisely and consistently focusing heat on parts to deliver an exact internal thermal profile.

Selective, localized heat

Induction heating allows heat to be applied to those areas being brazed without heating the entire assembly. With selective heat applied to the assembly, metallurgical changes are minimized, such as temper or anneal, along with part distortion when heating whole assemblies vs. only the braze joint interface. Additionally, brazing with a torch or flame in air causes oxidation, scaling and carbon build up on the parts that is minimized with the localized heating of induction.

Production line adaptability and integration

Radyne induction heating equipment in brazing and soldering applications is readily adaptable to production line methods, permitting strategic arrangement of the equipment in an assembly line. These value-added induction brazing systems can be configured for manual control, semi-automated, and all the way up to fully automated systems. High volume applications may incorporate robotics to pick and place parts and integrate into part flow with a conveyor system, carousel system or shuttle system to effectively and efficiently move parts. Induction brazing systems typically utilize brazing preforms or braze paste and can incorporate flux and paste dispensing equipment.

Improved fixture life and simplicity

Relatively simple fixtures to hold and align parts to be brazed are necessary regardless of the heating method used. The purpose of fixturing is to maintain proper alignment during the heating and cooling cycles so capillary action can take place while parts are within the induction coil. With localized heating prevalent with induction, fixture life is often extended as much of the fixture(s) are not subjected to heat compared to torch or furnace brazing. Simpler fixtures and fewer fixtures are typically needed for induction compared to furnace brazing.

Repeatable and reliable brazed joints

Induction brazing and soldering systems repeatedly provide clean, leak-free joints. The amount of energy put into a part can be controlled very precisely, assuming the part is consistently and accurately positioned relative to the inductor, making for a very controlled brazing process. Induction systems can store a “recipe” profile so that the same power and time is uniform each and every time a component is brazed. These “recipes” can be password protected once a brazing profile is established. Induction heating has less process variability compared to torch brazing as different operators use different techniques to braze and vary in how they adjust gas flow mixtures to achieve the desired flame (carburizing, reducing, neutral or oxidizing) for the brazing operation.

Improved Safety

Unlike flame or torch brazing, there is no open flame while using induction. Flame brazing requires fuel gases such as oxygen/acetylene or other bottled gases. These gases have fire and explosion hazards associated with them and these gas bottles need to be handled and stored properly. With the selective, localized heat of induction, only the targeted braze joint interface is heated without heating the nearby surfaces. Any combustible material (rags, wood, cardboard) near an open flame could ignite and needs to be kept away from the work station.

Conclusion

Not all brazing applications are strong candidates for induction heating. In situations of low volume, or high mix, or irregular shapes where fixturing or the coil design would be extremely complex, furnace brazing or torch brazing with experienced operators may be a more economical choice. However, Induction brazing allows for fast, controllable, precise, energy-efficient, repeatable braze joint for companies that embrace lean manufacturing.

As an induction heating industry leader, Radyne can help you navigate the challenges and realize the advantages of induction brazing. For more information on solutions for induction heating and related processes, please contact us.