Induction Pipe Coating Equipment and Processes

Pipe Coating

Radyne Pipe and Tube Coating Systems provide quality and high performance in pipe coating, heat treatment and preparation applications. Radyne offshore systems revolve around field joint processing, with a series of induction systems utilized for heating and coating of field joints on pipe laying vessels.

Modern technology has placed increased emphasis on coatings’ corrosion protection, electrical characteristics, thermal properties, appearance, and other special properties. Such coatings have included simple lacquers and paints, plastics, ceramics, metals, and various chemical conversion coatings. Induction heating has found increased application for coatings which must be ‘cured’ or ‘dried’ rapidly. This process is suitable for either drying pipe after alkaline cleaning and rinsing, or for curing coating applied to the surface.

Induction heating is particularly applicable to high-speed continuous coating lines. Since heating occurs in the pipe as it passes through a coil, it’s heated almost instantaneously to a controlled temperature. This allows a short heating zone for processing, preventing problems associated with a shutdown in the processing line, such as excess heating of the wire coating. Integration of an induction heating operation is simple because of heat control and ease though the induction coil.

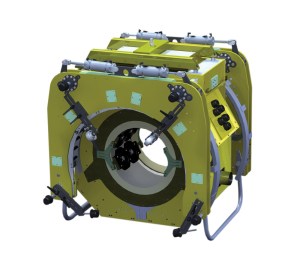

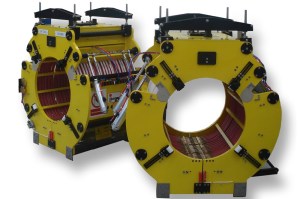

Merlin Pipe Coating Systems

Renowned across the gas and pipe processing industries, Radyne Pipe and Tube Coating Systems provide the highest levels of quality and performance in pipe coating, heat treatment and preparation applications. Radyne offshore systems revolve around field joint processing, with a series of induction systems utilized for heating and coating of field joints on pipe laying vessels.

Offline Pipe and Tube Coating Systems

Onshore based applications include tube bright annealing, line pipe preheating prior to coating, and pipe-end heating.