Heat Treating

Hardening and annealing are the two major applications for induction heating.

Hardening falls into two general classes, through hardening and case hardening. Basically, the methods employed to through harden or case-harden are the same. The major difference occurs in the method of applying the heat and the method of applying the quench.

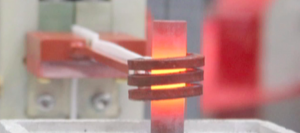

Induction heat treating: This is one of the most common uses of induction heating and compares favorably with furnace hardening due to the ability of induction heating to harden selective areas, extremely quick, is easy to adapt to cell manufacture, can heat treat one component at a time for example for prototyping is started instantly and is more efficient. Induction heating is the heating of metallic components, not necessarily ferromagnetic, by applying an electrically alternating field to that metallic object utilizing an induction coil arrangement, the electrically magnetic field causing heating by virtue of hysteresis and resistive losses in the metallic.

By rapidly heating and quenching a steel component, the heat can be confined to the surface layer only and a case-hardened surface may be produced. For an annealing or forging operation the component would be heated more slowly, allowing the heat to soak into and through heat the component.

Annealing can be classified as a heating and cooling operation with a relatively slow cooling operation taking place. This type of heat treatment is used primarily to remove stresses; rearrange crystalline structure; change ductility, toughness, electrical magnetic or other physical properties. The temperature at which the operation takes place and the rate of cooling classify the type is decreased and ultimately the expense of the overall process.

In induction heating, a phenomenon occurs referred to as “skin depth”, “reference depth” or “penetration depth” and which represent the depths to which a majority (approx. 80%) of the current flows in an induction heating field. This penetration depth varies according to the operational frequency of the induction heating.

Skin effect: At frequencies used for induction heating, current tends to flow in the surface of the conductor. This is because of the higher flux density at the center conductor increases the impedance of the inner filaments of the conductor. The resultant high surface current density causes rapid heating which is confined to a thin skin on the surface of the component.

Induction heating is used extensively for hardening, tempering, and annealing, in forging for the heating of billets, heating of bar ends, heating of steel slabs, tube heating prior to bending and prior to stretch reduction, melting of metals, joining applications such brazing, soldering, and shrink fitting.

If the temperature of the steel is raised to hardening temperature, a reaction in a solid state takes place, forming a new solid solution called austenite. This temperature is known as the lower critical temperature. If the steel has an excess of ferrite or cementite and the temperature increased until all of the ferrite or cementite was absorbed into the solution, the upper critical temperature would be reached.

In heat treating applications, tools are used to specific projects and heating. Induction tooling refers to the induction coil and, where applicable, the quenching head. Induction coils are not strictly coils. They can be of many different shapes, the most common of which is a helical arrangement which surrounds the periphery of the component to be heated. This represents the most efficient arrangement, however, for there are certain areas that may require to be avoided during heating. This is also true of other applications such as brazing and shrink fitting and under those circumstances, the induction coil will be tailored to suit that particular area to be heated.