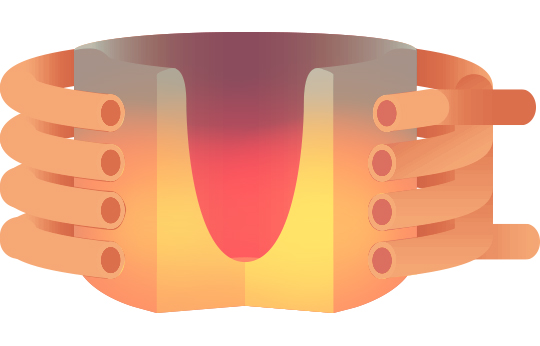

Induction Melting

For many processes, induction melting is the first step in producing a useful product. Induction equipment is custom-designed for each application to ensure it is as efficient as possible. Induction coil designs support volume ranging from just pounds of material to tons at a time. Frequency and power tuning allows for processing virtually all metals and materials including iron, steel and stainless steel alloys, copper and copper-based alloys, aluminum, silicon, and more.

Induction Vacuum Melting

Because induction heating is accomplished using a magnetic field, the work piece (or load) can be physically isolated from the induction coil by refractory or some other non-conducting medium. The magnetic field will pass through this material to induce a voltage in the load contained within. This means that the load or work piece can be heated under vacuum or in a carefully controlled atmosphere. This enables processing of reactive metals (Ti, Al), specialty alloys, silicon, graphite, and other sensitive conductive materials.