Crystal Growing

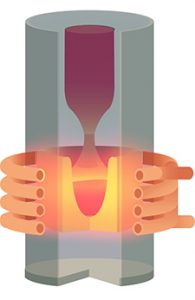

Successful production of transistors requires production of single crystals of germanium or silicon with a known orientation. This has been most often accomplish by the Czochralski technique, involving use of a seed crystal of proper orientation slowly withdrawn from the melt, “crystal pulling”. If the melt is maintained at proper temperature and within very narrow limits, the molten materials adheres to the seed as it is withdrawn and grows over it to form a single crystal upon solidification. In this country, high frequency induction heating has generally been used to maintain the metal at temperature.

Induction heating provides the very accurate temperature control required for successful crystal growth. Radyne makes a range of power supplies that incorporate special controls to ensure accurate delivery of power to the load. Due to the temperature ranges of the susceptor materials used in various applications, coil design and frequency selection is critical to achieve the desired results.

Crystalline Material Production processes typically involve heating a susceptor material such as Graphite, Molybdimum, Tungsten or Silicon Carbide that is placed in a controlled inert atmosphere or vacuum chamber. Heat cycles are continuous and tightly controlled over the production cycle. Restart electronics enable a crystal growing process to resume following a power outage.