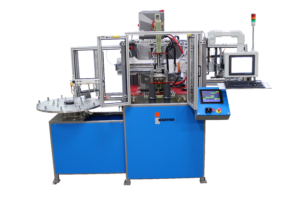

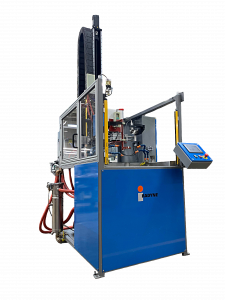

FlexScan® Lift and Rotate Induction Heating System

Introducing FlexScan® Lift and Rotate Induction Heating System: Affordable Innovation

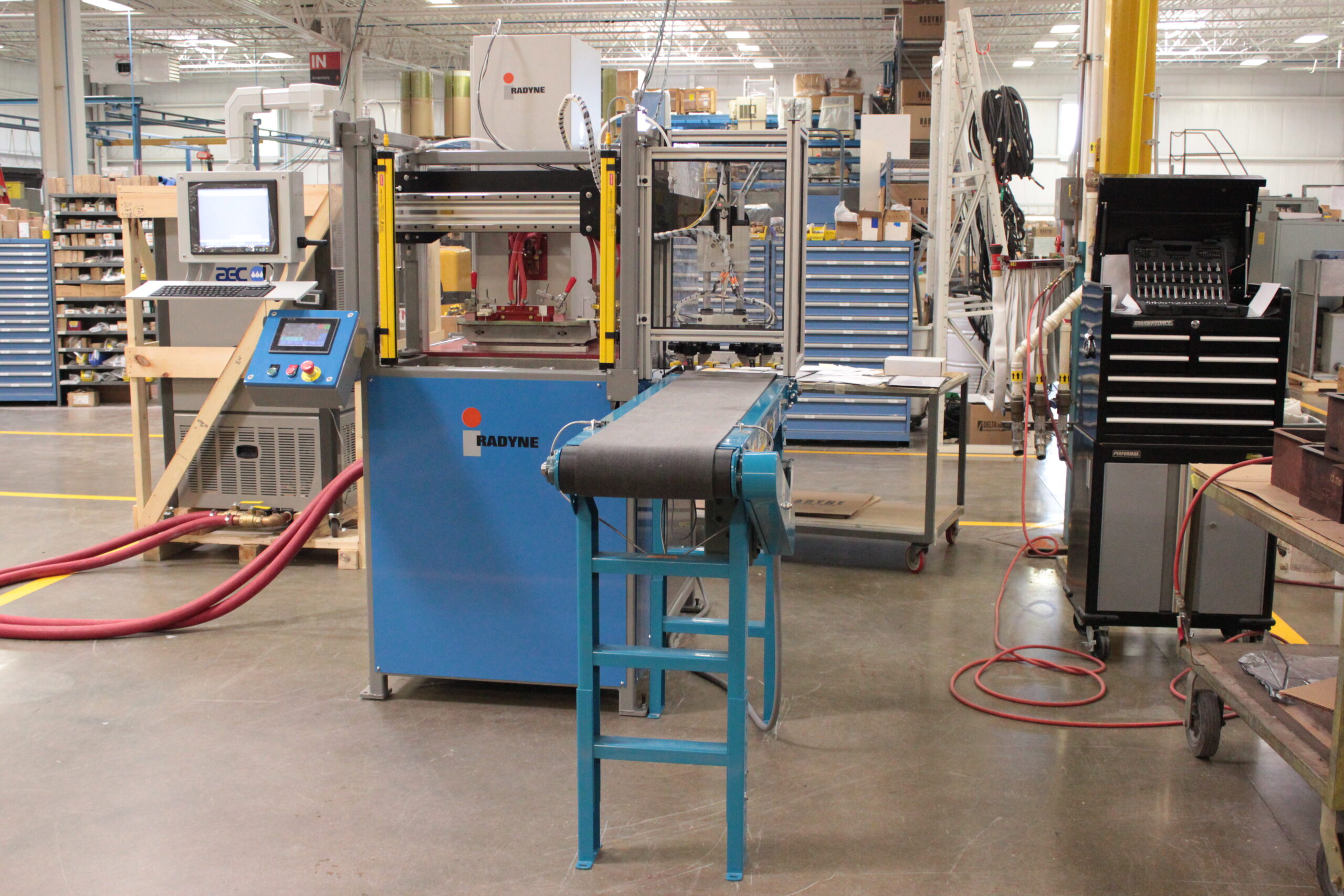

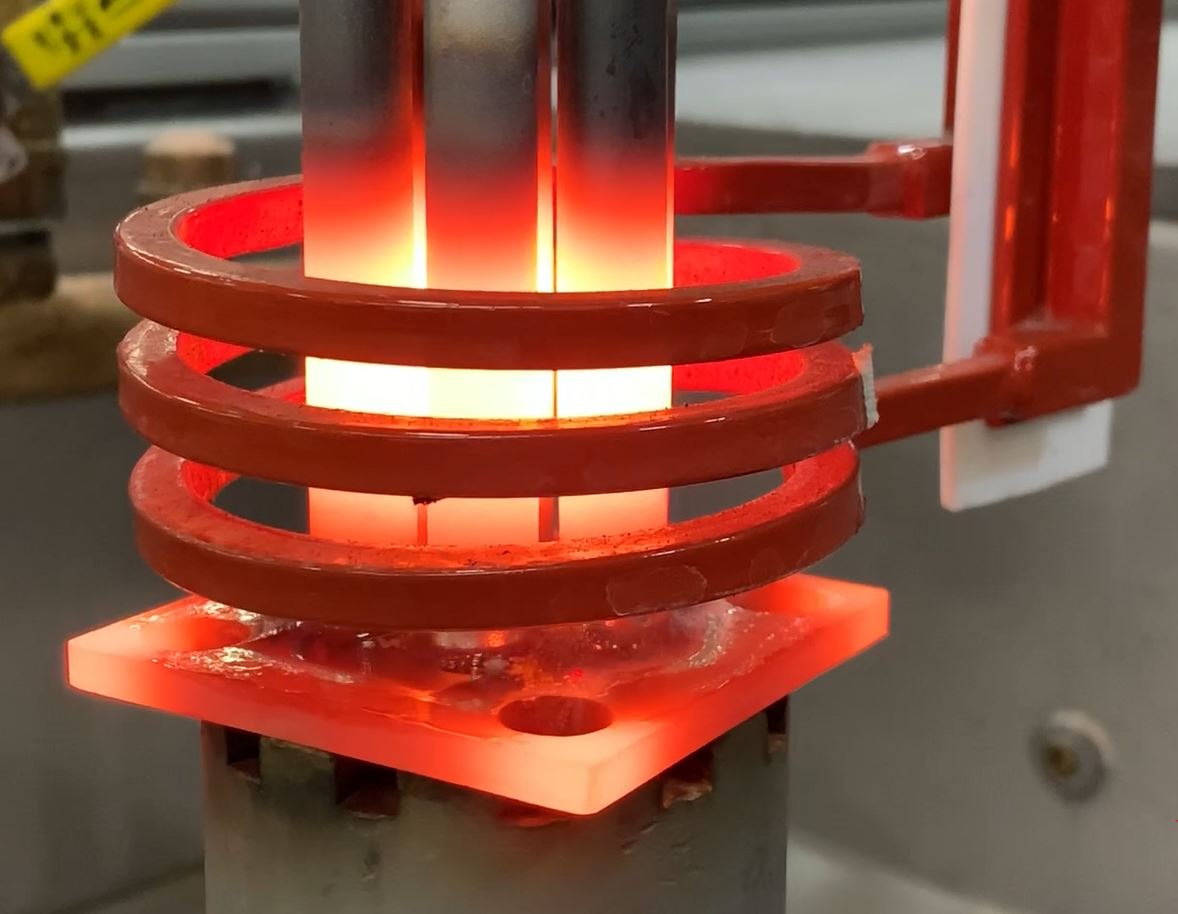

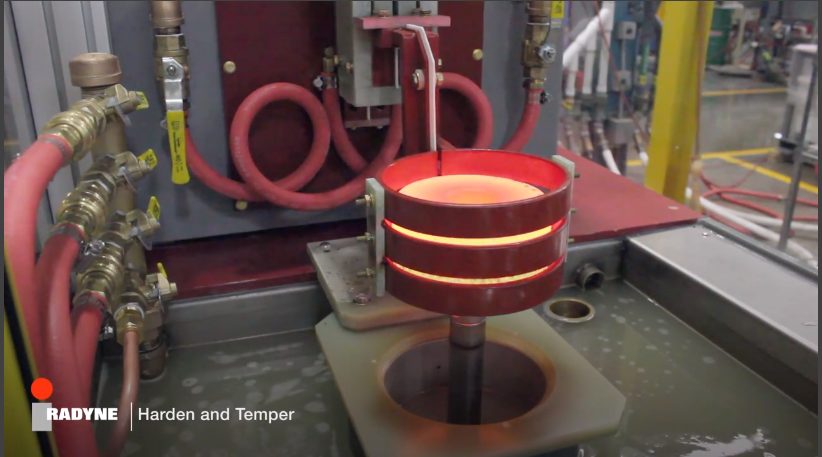

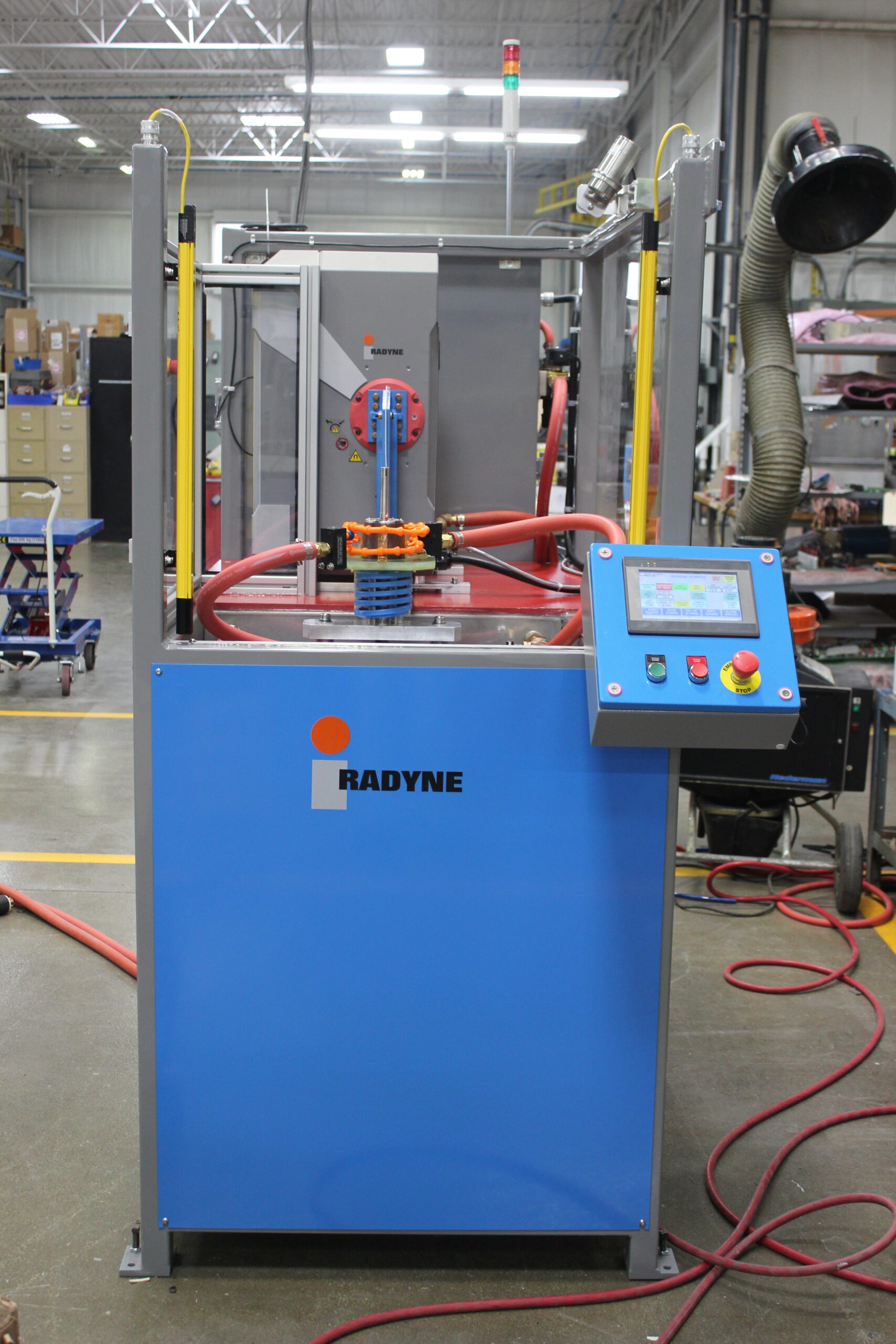

Break new ground with the FlexScan® lift and rotate induction heating system, the marketplace’s most cost-effective induction heating solution. Designed to revolutionize heating processes, Radyne’s FlexScan® offers versatility for a wide range of applications. Our FlexScan® systems combine economy, modularity, and adaptability, making them a perfect fit for small and large operations alike.

Modular Design for Enhanced Adaptability

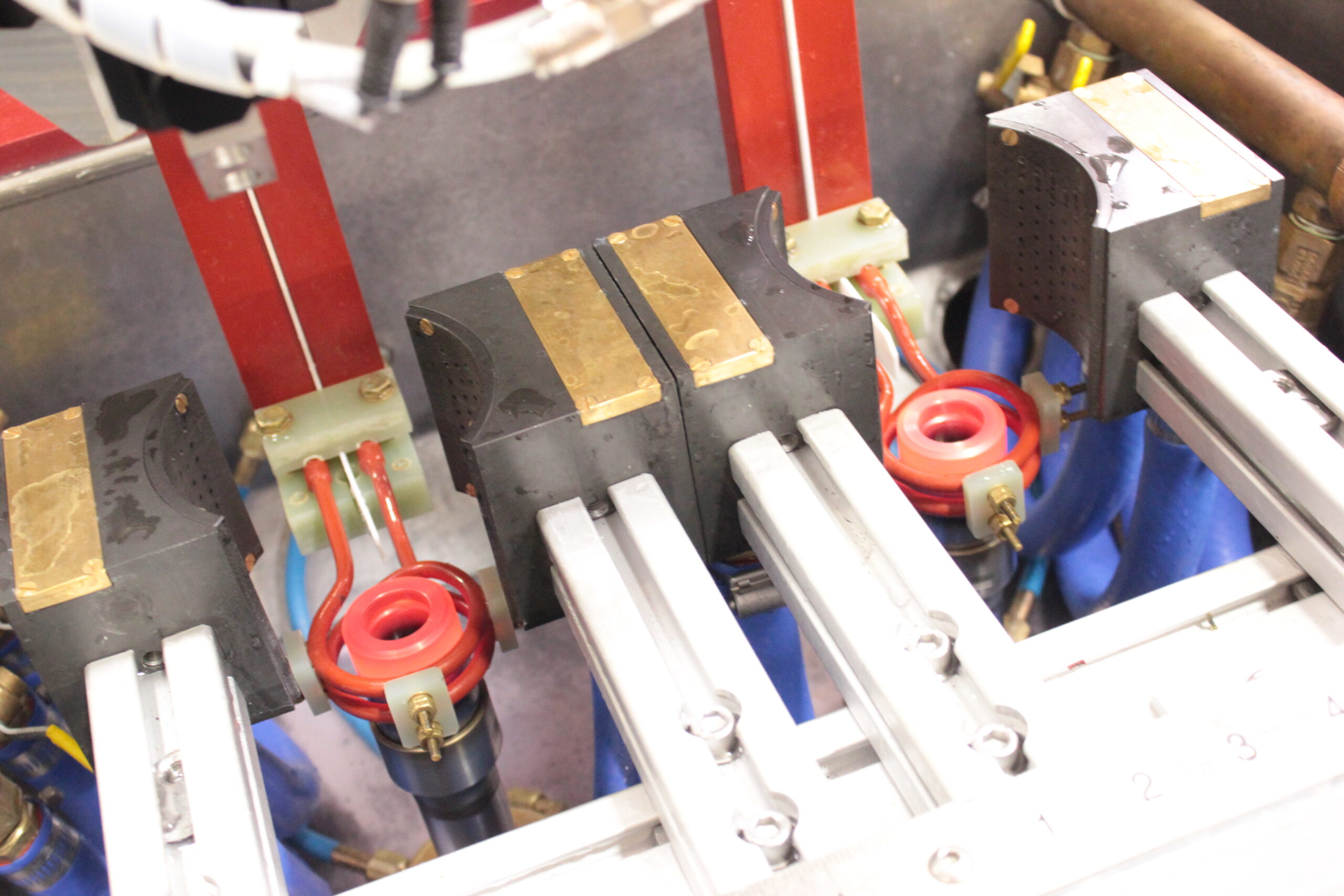

The strength of the FlexScan® system lies in its adaptable modular design, perfect for various manufacturing needs. You can choose different power supplies based on your power requirements, even using multiple supplies for dual operations. The systems include flexible Lexan guarding that’s easy to customize for special material handling needs and unique requirements. For parts with distinct shapes, FlexScan® systems can be equipped with a wide array of specialized tooling and fixturing. And when it comes to heating applications like heat treating, brazing, soldering, shrink fitting, and heat staking, FlexScan® truly stands out.

Seamless Operator Interaction

FlexScan® prioritizes user-friendliness. Our systems arrive pre-configured by our experts, ensuring optimal outcomes. Equipped with our Digital IQ control firmware, FlexScan® systems boast programmable recipes that maintain process consistency and repeatability. This firmware also facilitates ethernet connectivity, enabling remote control of one or more systems. The result is a system that’s effortlessly user-friendly, promotes operator safety and minimizes training requirements. FlexScan® systems can also be optioned with our MOTUS touchscreen controls for enhanced motion control.

Unlock the Potential of a Lift and Rotate Induction System

Unlock the Potential of a Lift and Rotate Induction System

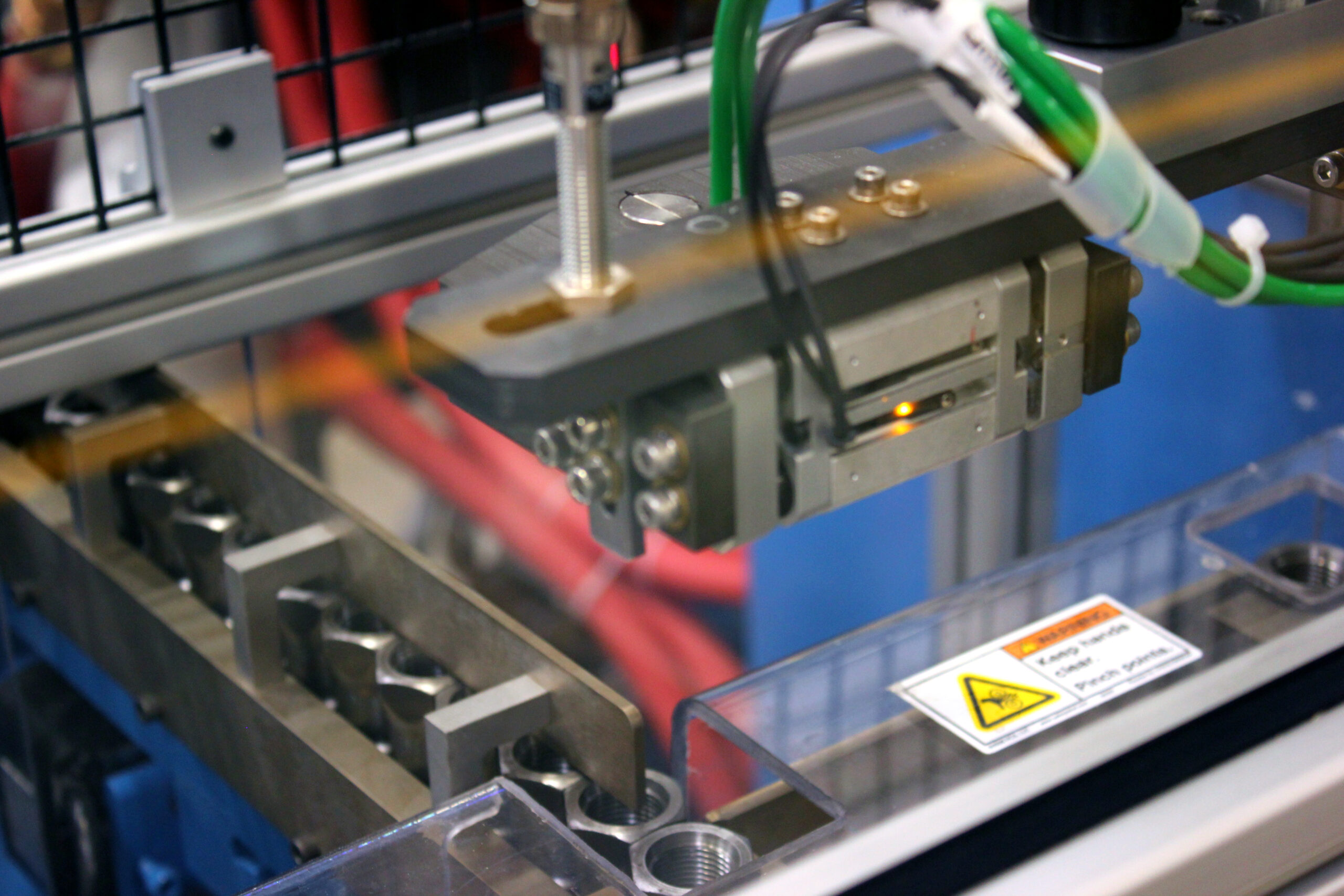

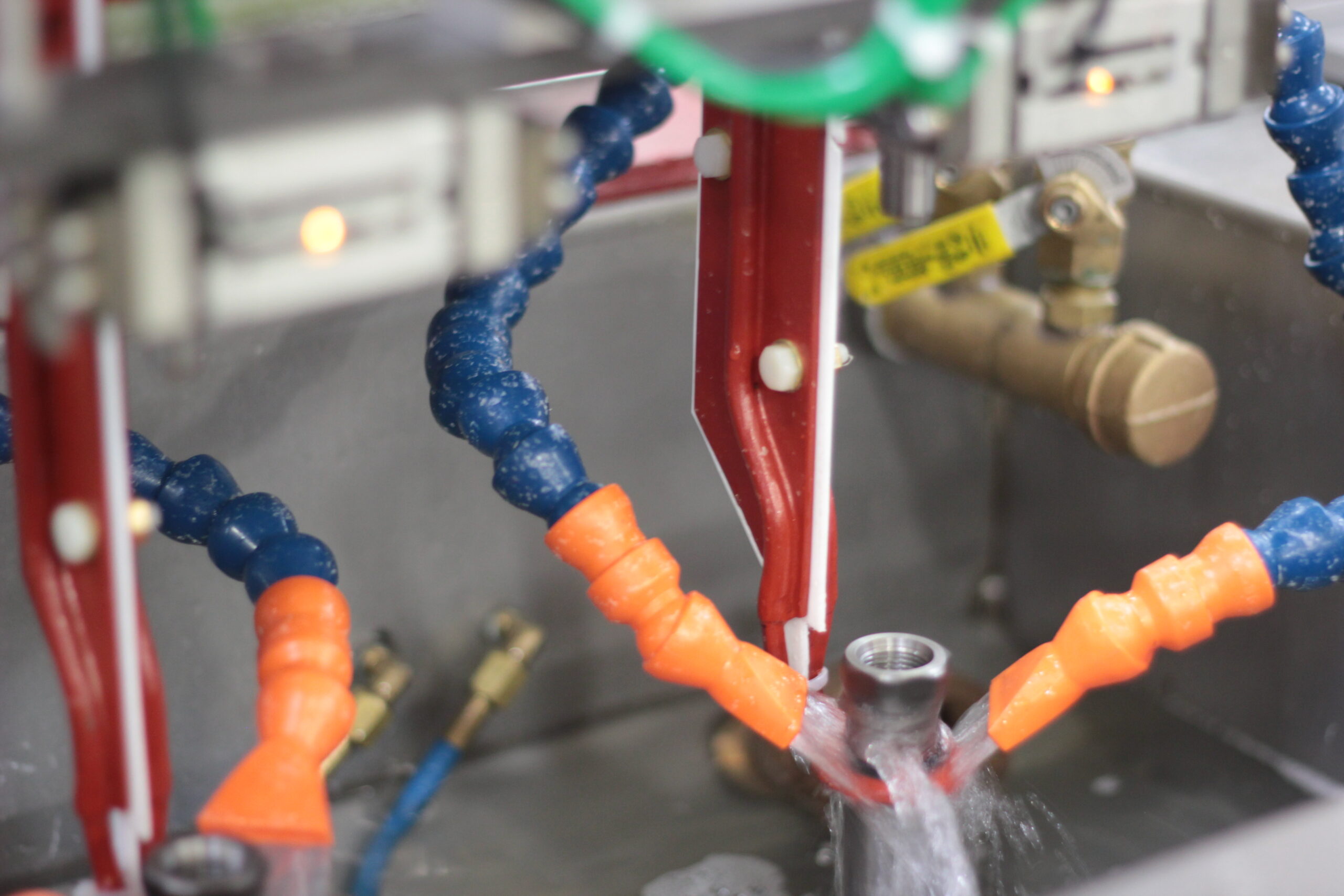

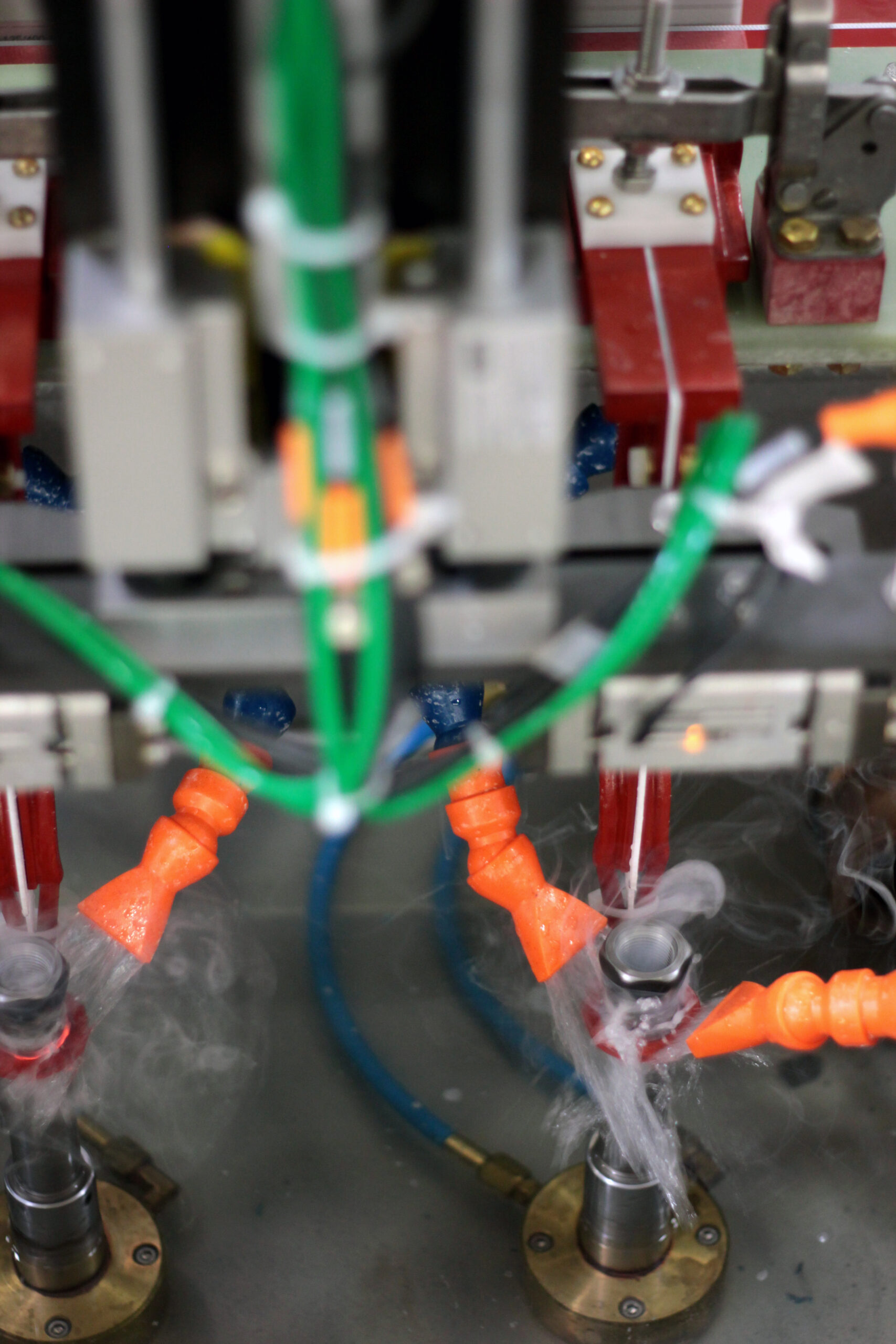

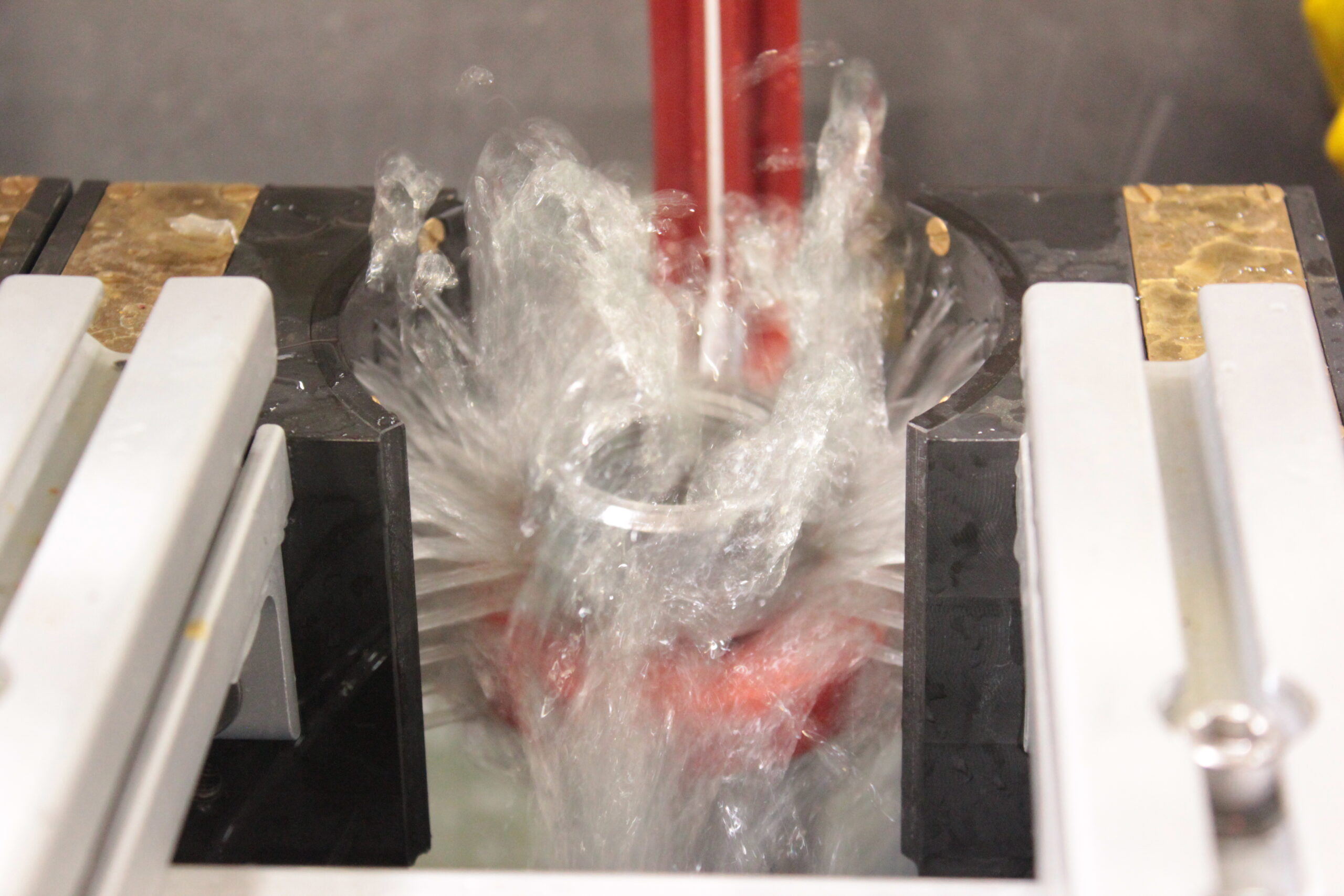

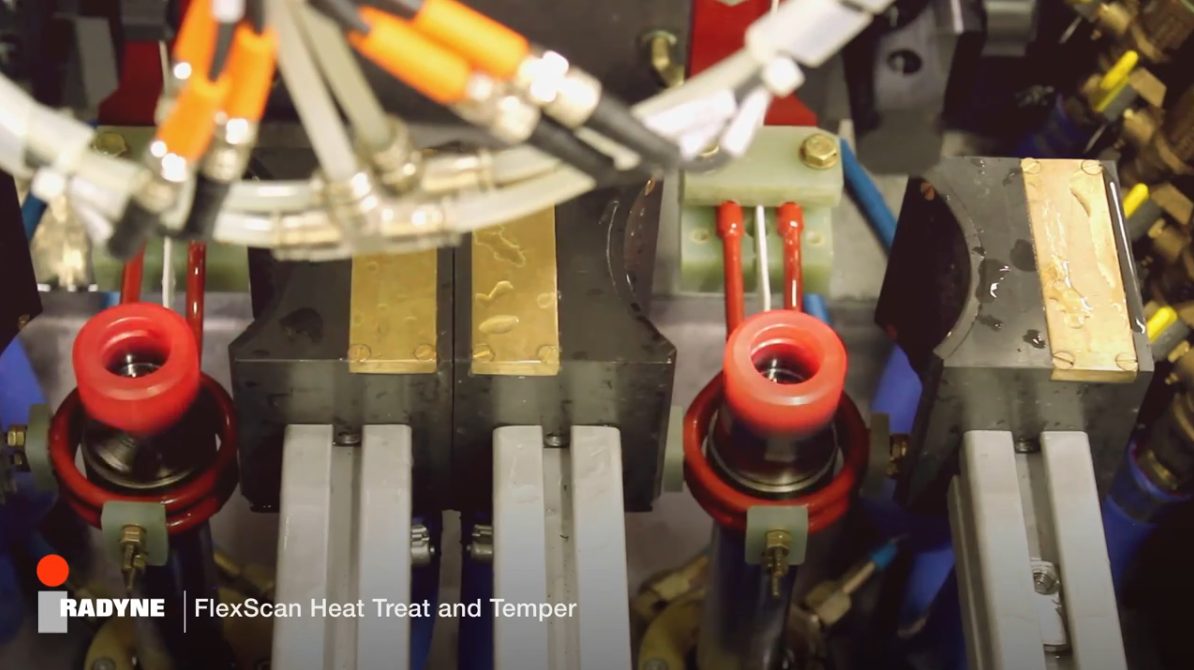

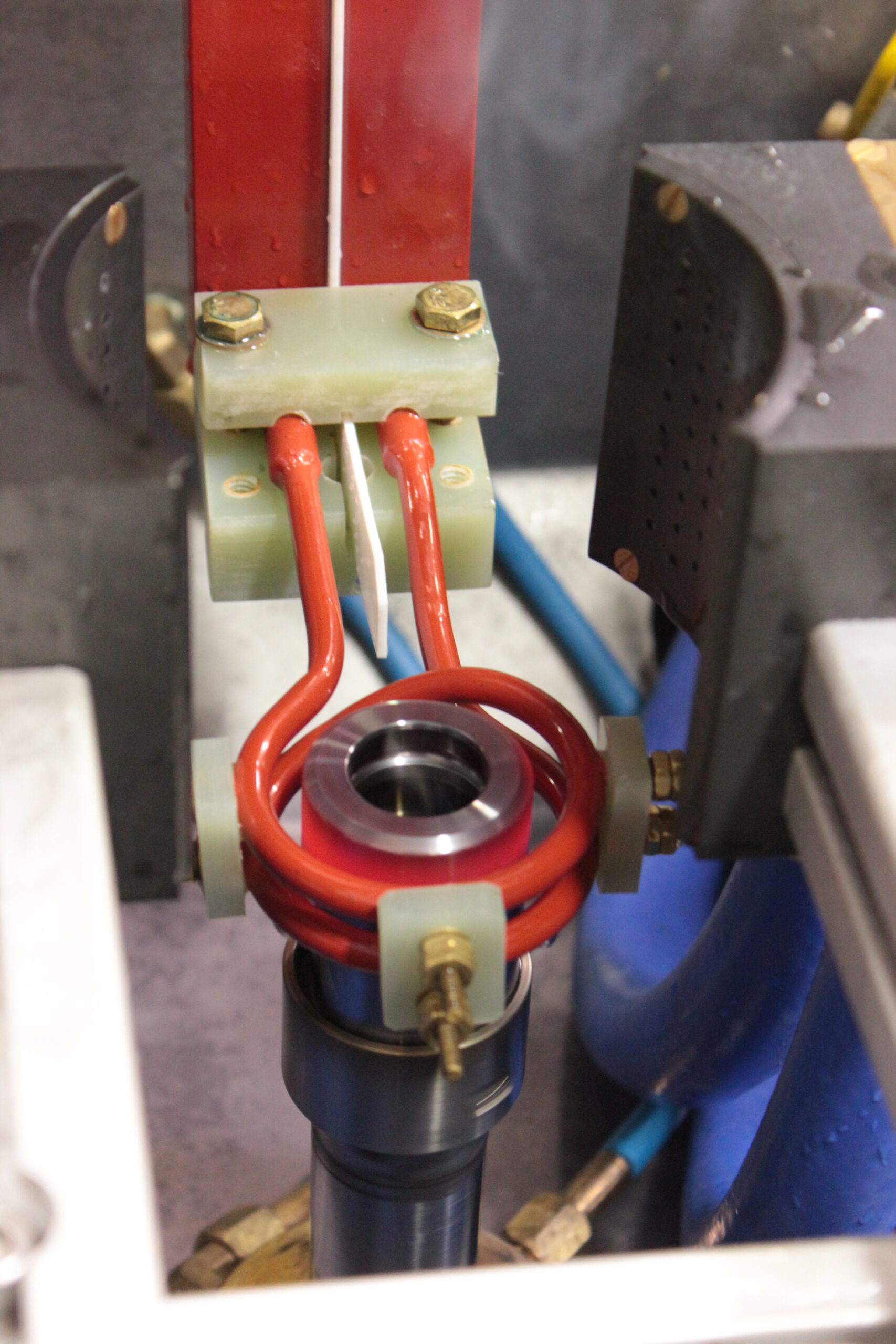

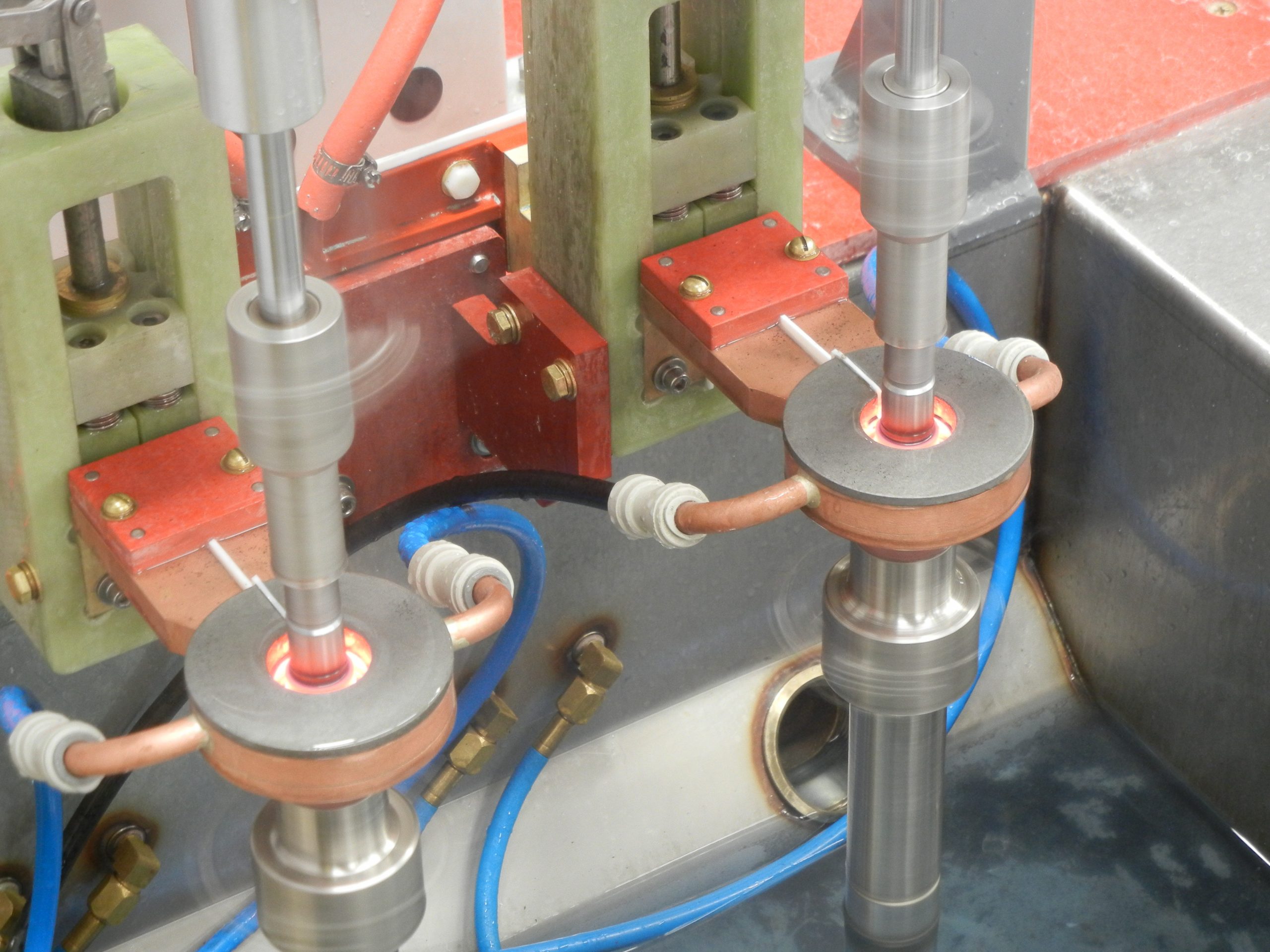

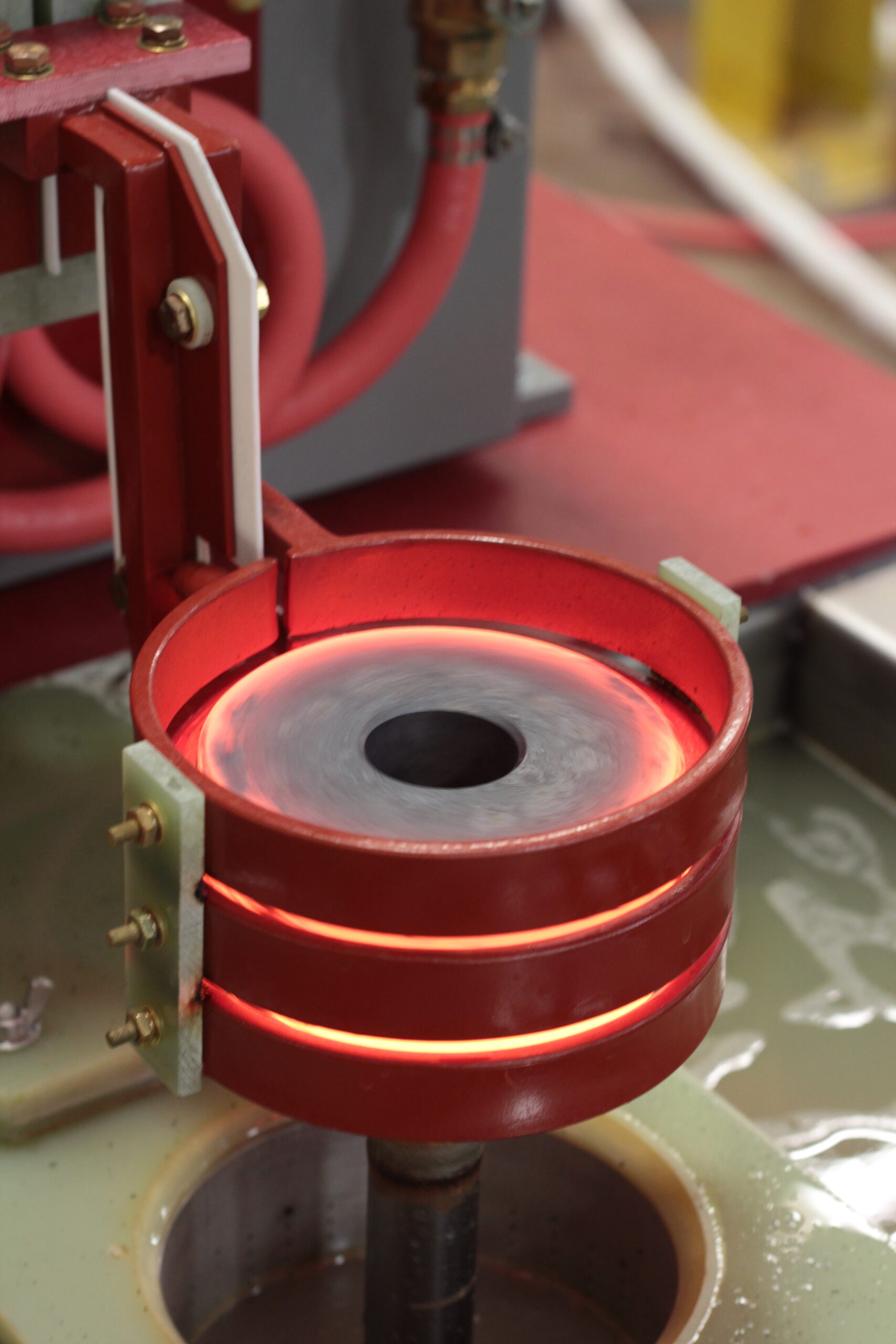

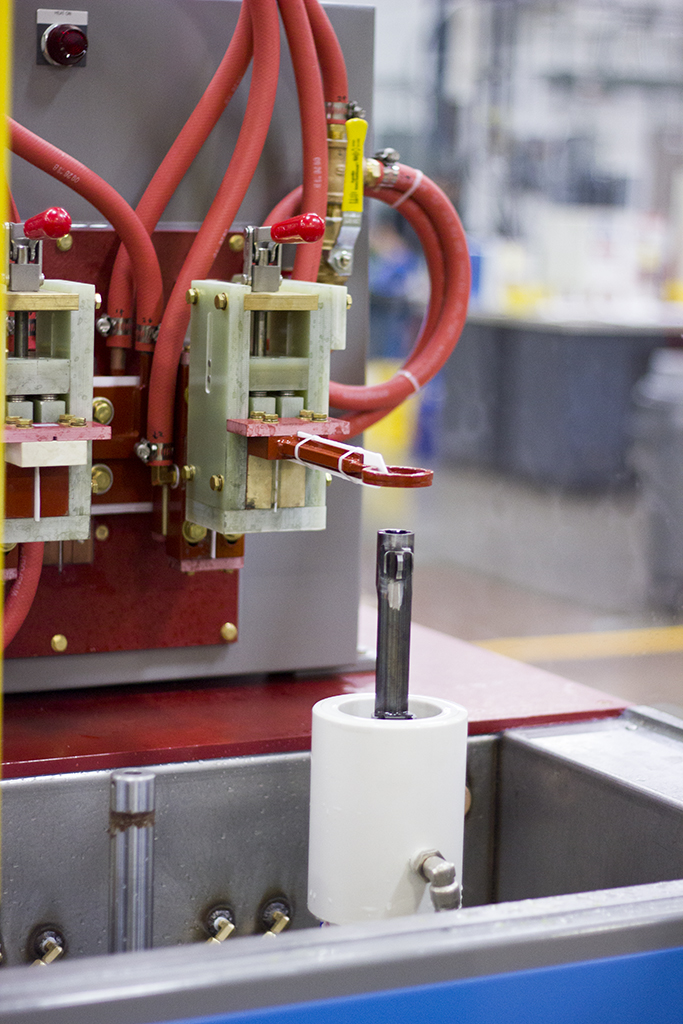

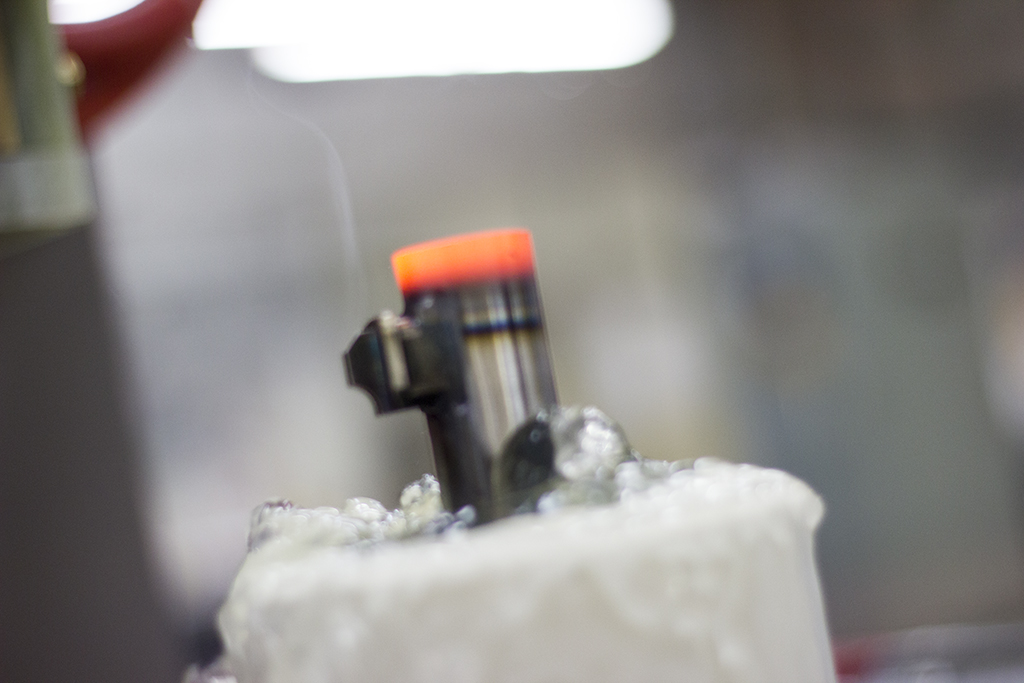

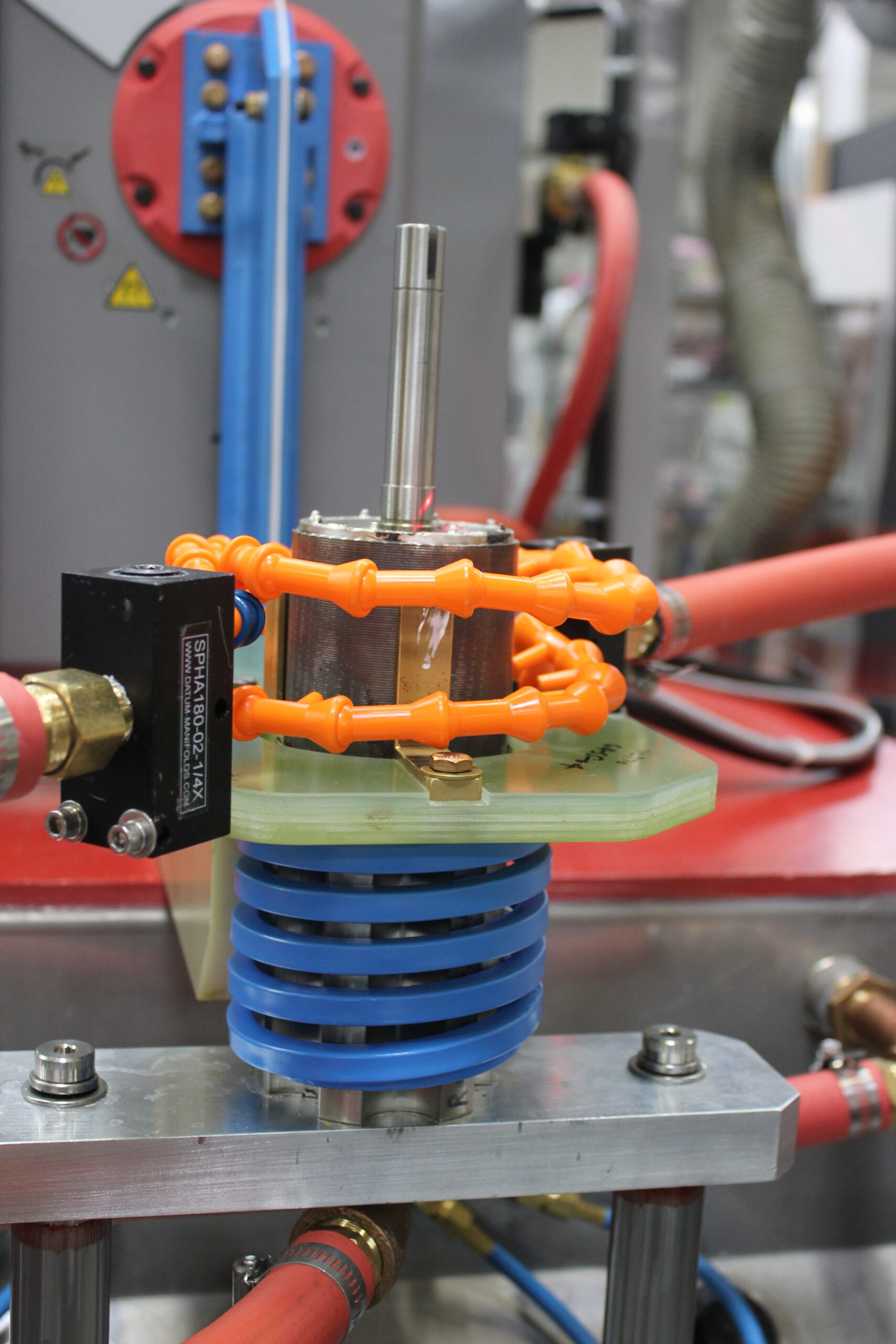

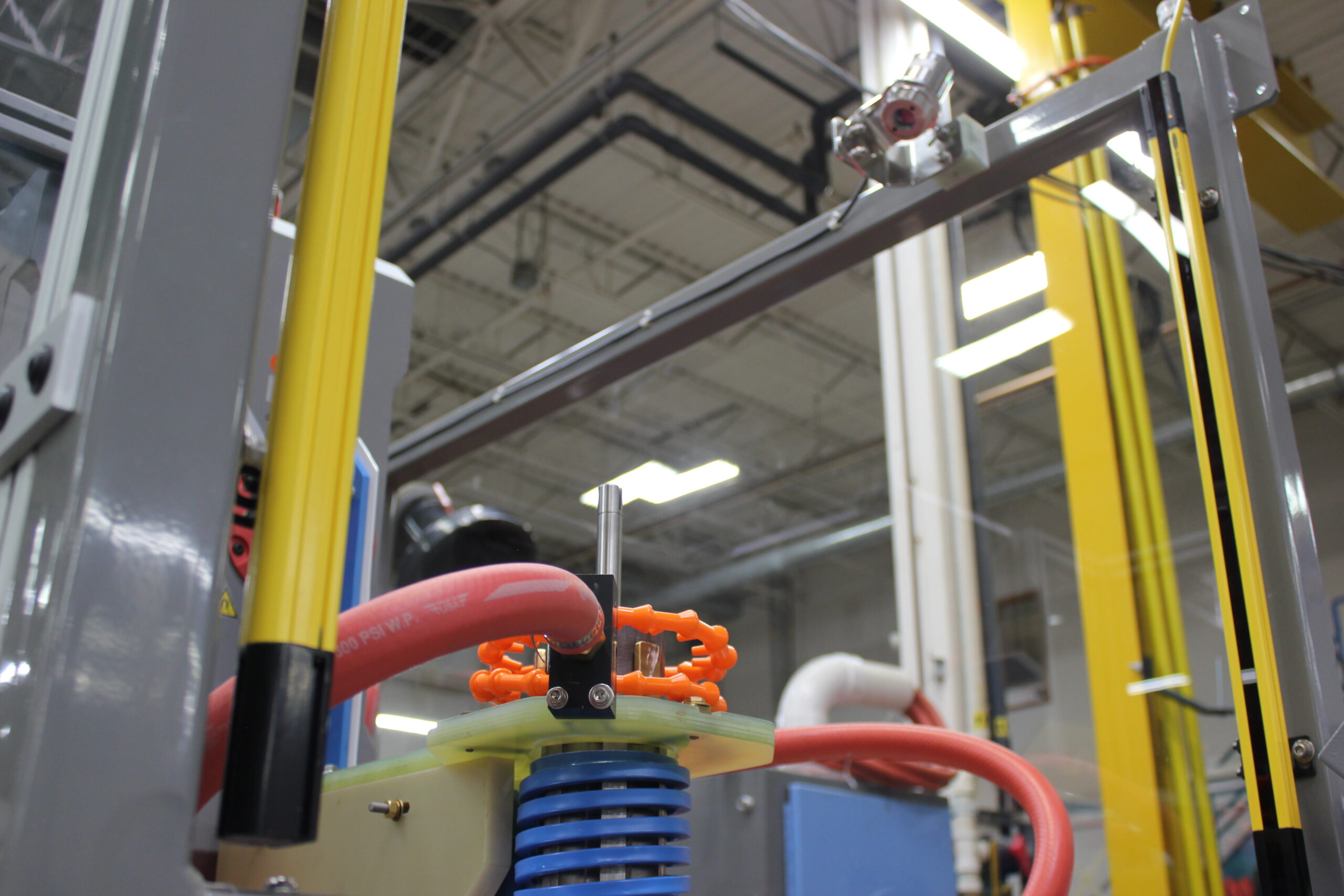

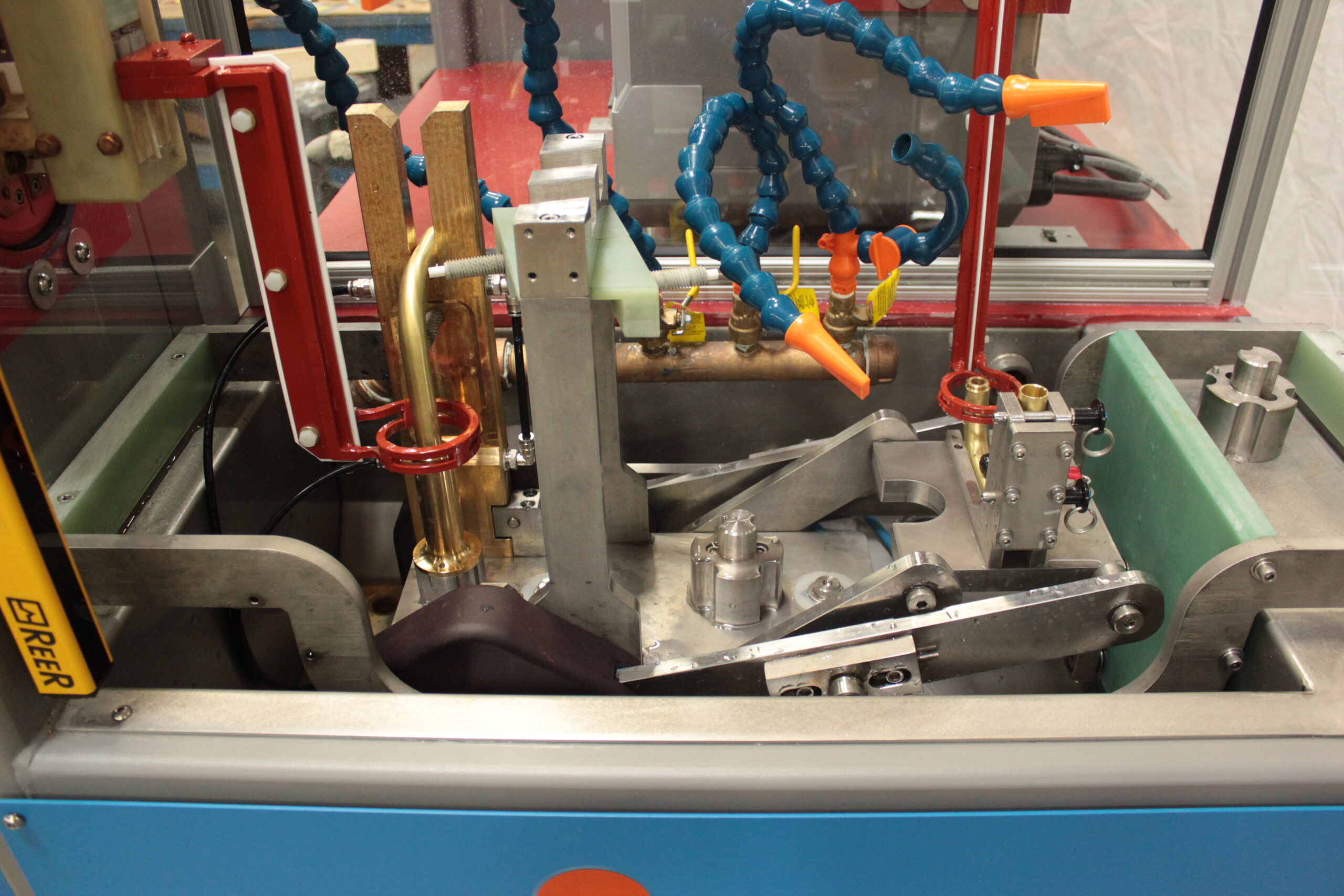

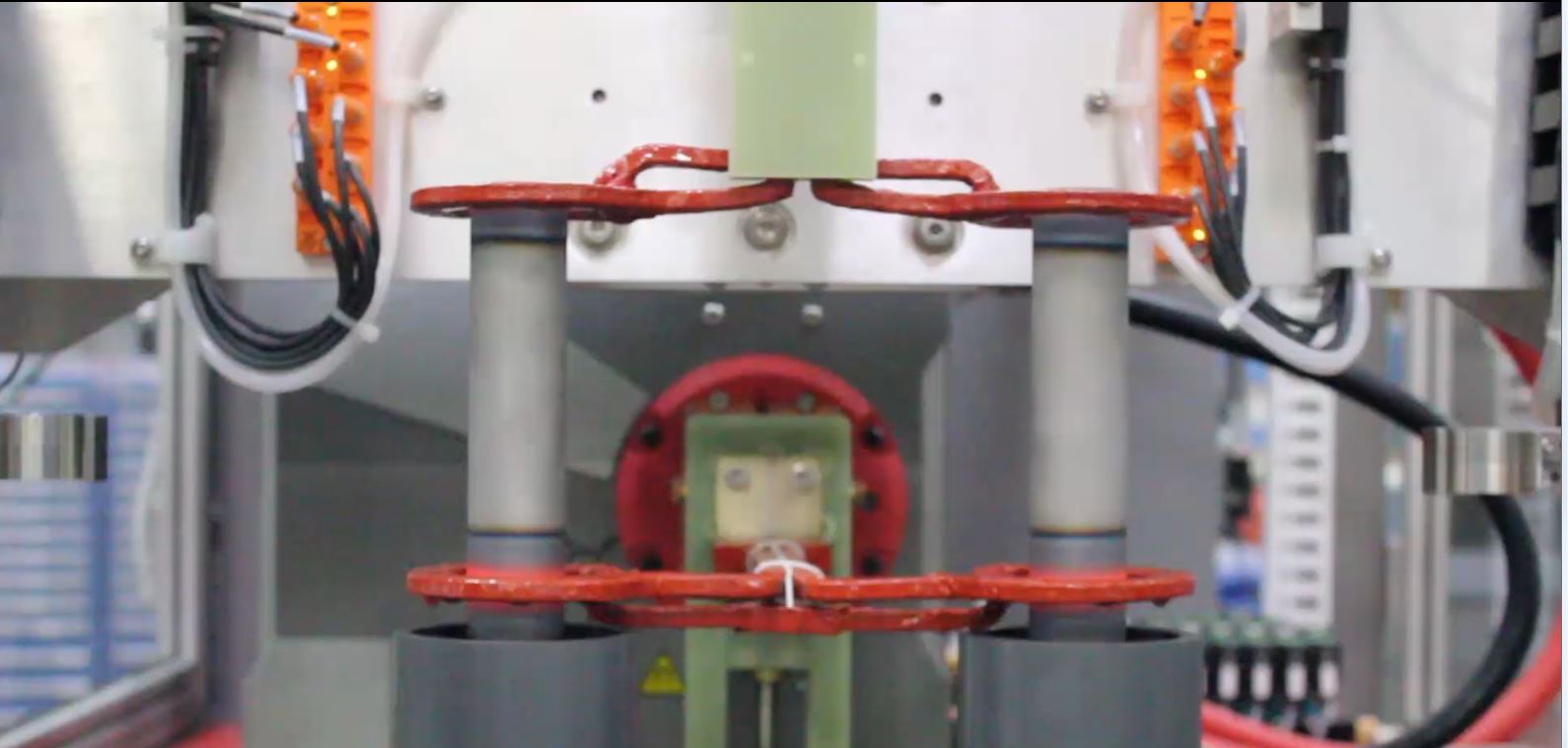

Discover the versatility of the FlexScan® lift and rotate induction system. This adaptable platform serves a multitude of processes, including heat treating, brazing, soldering, shrink fitting, and heat staking. The system features single or dual spindles extending from a stainless steel sink basin, ensuring corrosion resistance. The spindles offer 12 inches of vertical travel and a maximum rotation speed of 185 rpm.

FlexScan® is a game-changer in enhancing throughput and task repeatability. The system accommodates both manual loading and seamless adaptation to automated material handling and robotic loading/unloading. With a focus on space efficiency, the compact design conserves valuable floor space.

Features

- Single or Dual Spindles: Achieve enhanced efficiency with systems featuring single or dual spindles for running one or two up operations.

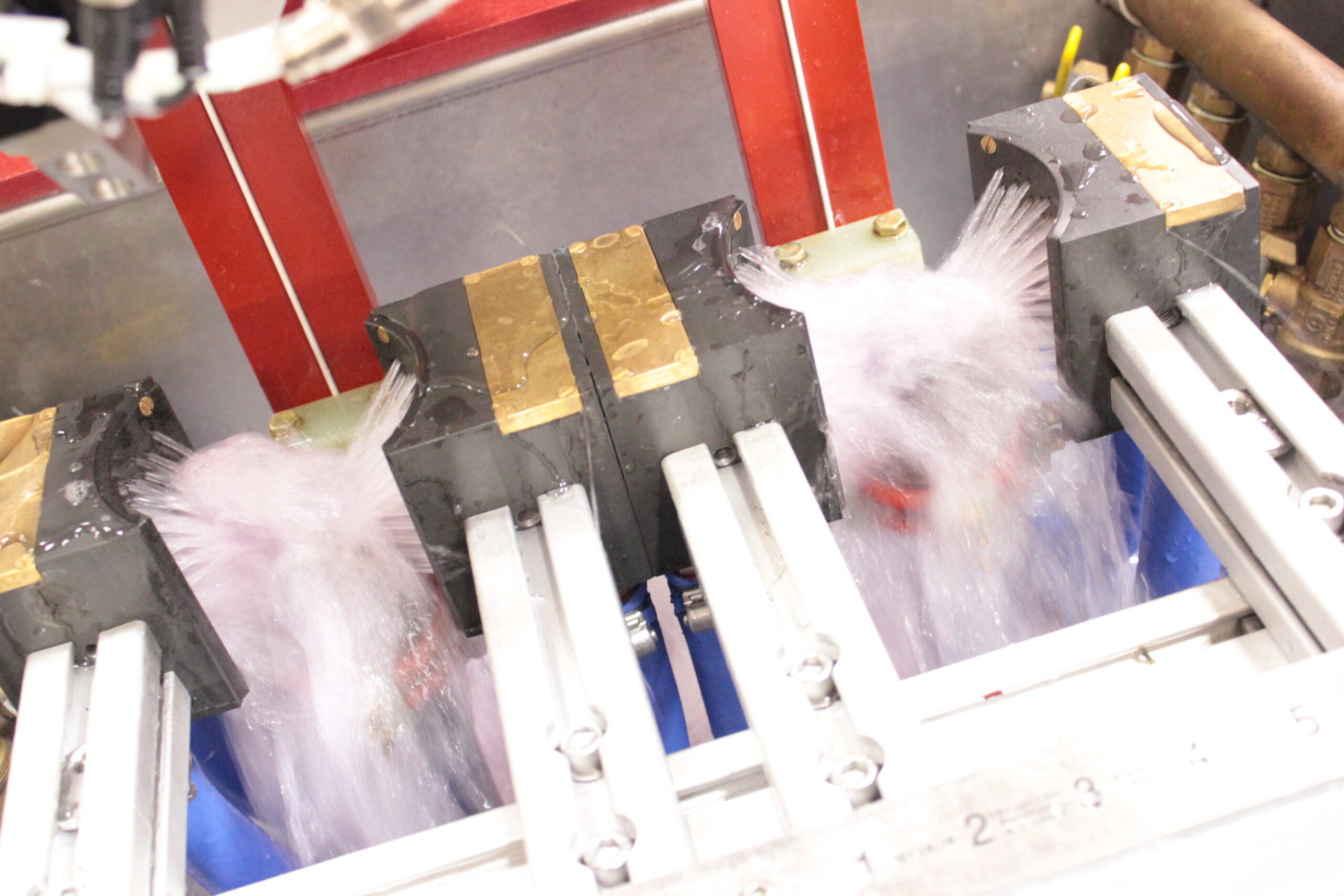

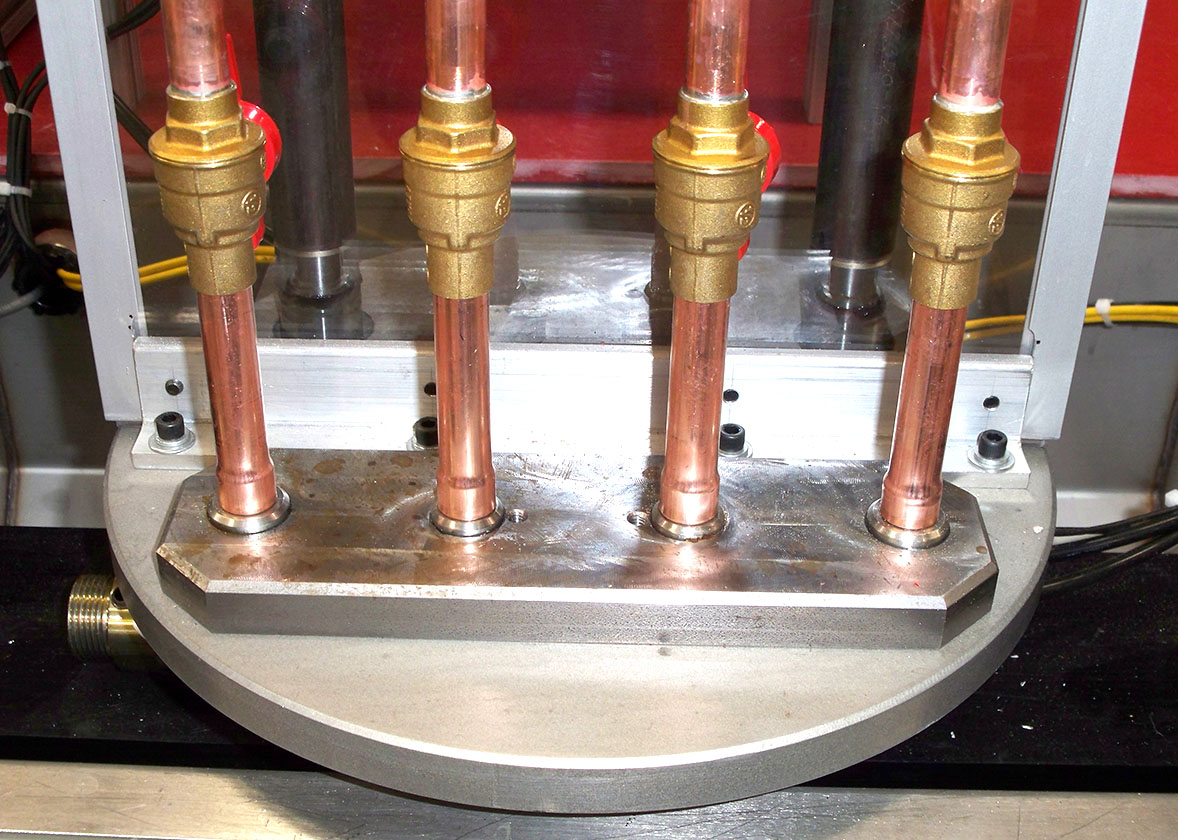

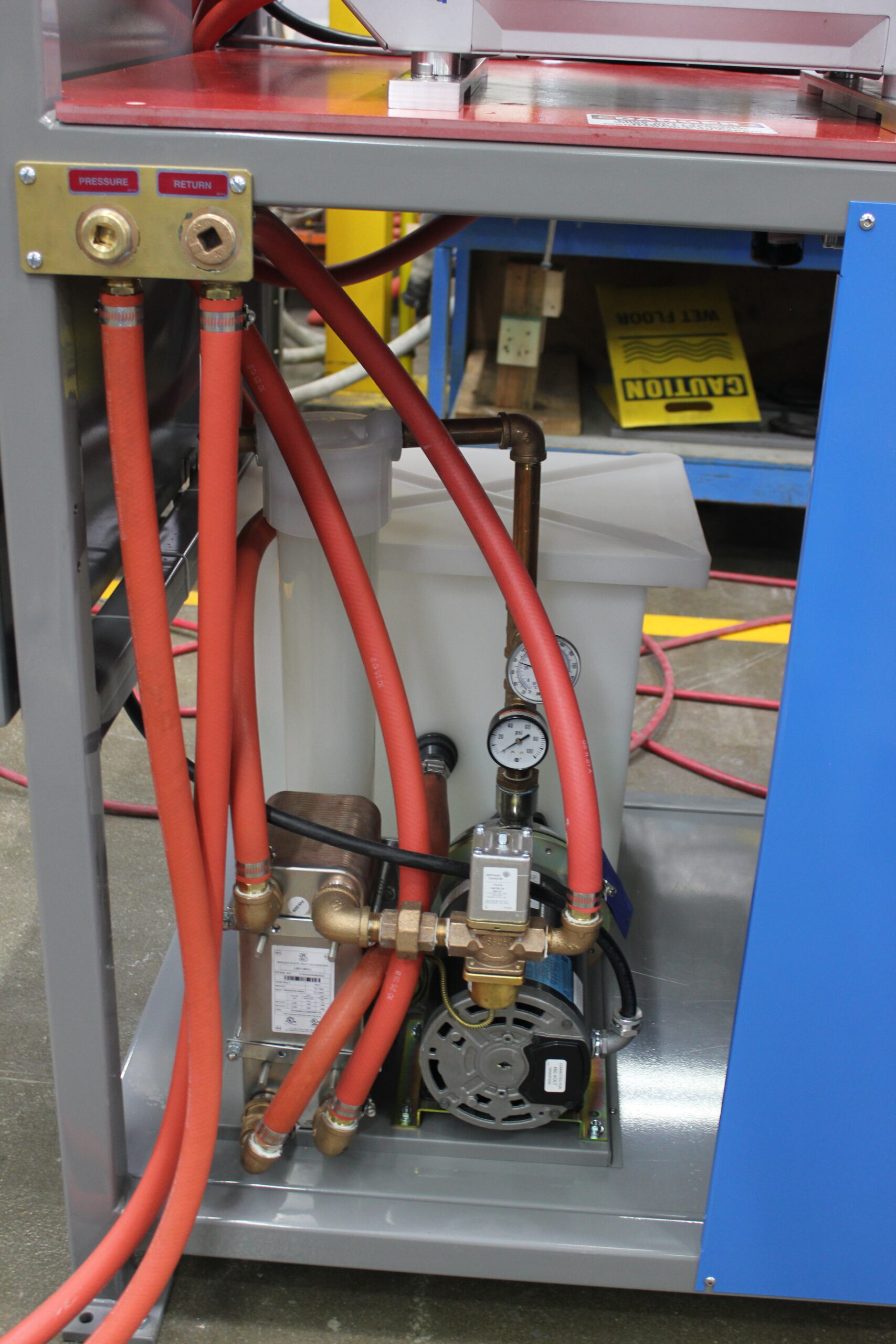

- Stainless Steel Quench Basin: Our systems feature a built-in stainless steel sink basin designed to resist corrosion.

- Motorized Upper Center Spindle: Changeovers made easy. Our systems come with a motorized upper center spindle, allowing for quick and convenient adjustments. Experience efficient production transitions and reduced downtime with Radyne’s advanced technology.

- Self-contained System for Work Cell Integration: Seamlessly integrate our self-contained induction systems into your work cell. Benefit from hassle-free setup and precision heat-treating that enhances your manufacturing processes.

- Application-Matched Precision Hardening: Tailor your operations with different power supply ratings and frequency ranges available for application-matched precision heating. Achieve optimal results with technology designed to meet your unique needs.

- Simple Utility Connection: Experience fast and cost-effective installation with our induction systems featuring simple utility connections. Get your operations up and running swiftly with Radyne’s easy integration and installation services.

| FlexScan 12 | FlexScan 12XL | |

|---|---|---|

| Scan Length | 12 in [30 cm] | 12 in [30 cm] |

| Spindles | Single or Dual | Single or Dual |

| Spindle Spacing | 8 in [203 mm] | |

| Max RPM | 185 RPM | |

| Max Payload | 75 lbs [34 kg] | |

| Max Part Diameter (1-Up) | 8 in [203mm] | |

| Max Part Diameter (2-Up) | 6 in [152 mm] | |

| Machine Dimensions (without power supply) | W: 42 in [107 cm] D: 38 in [97 cm] H: 80 in [203 cm] | W: 42 in [107 cm] D: 78 in [198 cm] H: 80 in [203 cm] |

| Quench Tank | 35 Gal/20 GPM [132 L/75 LPM] |

Optional Technology

- Quick Disconnect Coil Mounting: Elevate efficiency with quick change tooling and coil mounting. Experience rapid change-overs with Radyne’s Quick Disconnect technology.

- Robotics and Material Handling Integration: Revolutionize your operations by integrating robotics and material handling with your ScanMaster™ system. Our technology seamlessly accommodates integrated bowl feeders, rotary tables, step feeders, conveyors, and 6-axis robotic arms, enhancing your workflow.

- MOTUS Touchscreen Controls: Simplify your workflow with Radyne’s user-friendly Motus controls that streamline setup, changeover, and diagnostics. Radyne’s systems make precision heating accessible and efficient.

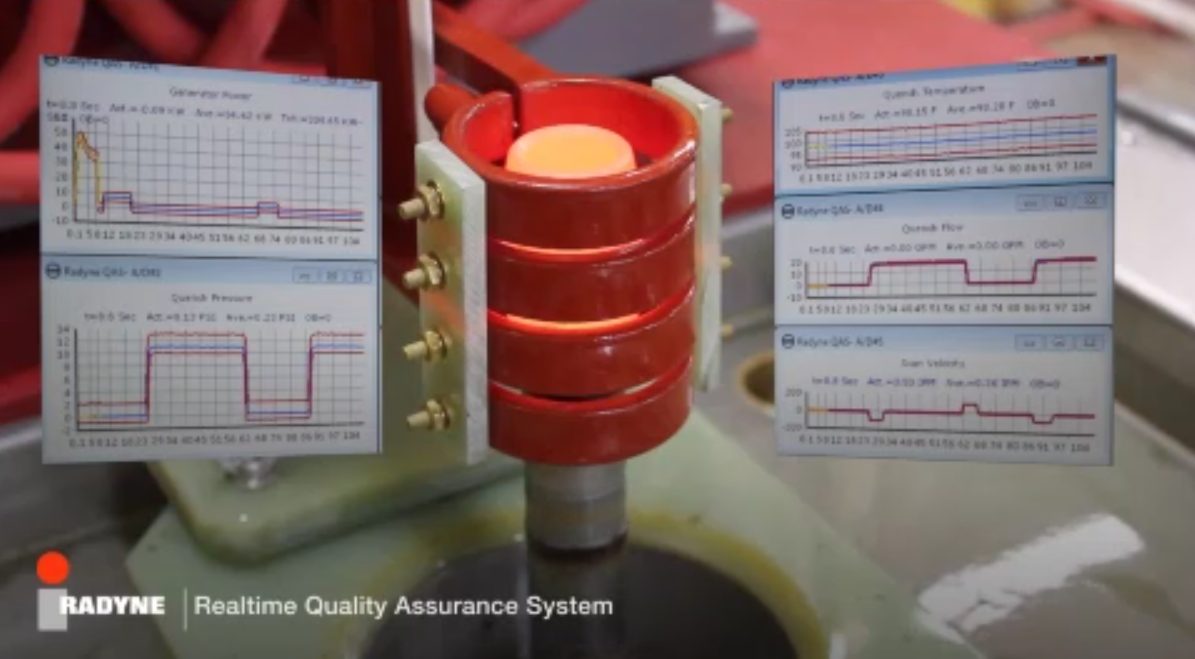

- QAS Monitoring and Alerting System: Elevate your process monitoring and traceability with the QAS Monitoring and Alerting System. Gain insights into each part processed, enhancing your quality control and production efficiency.

- Remote Quench Pod or Quench Media Exchanger: Enhance the control and flexibility of your ScanMaster™ system with a remote quench pod or quench media exchanger. Streamline your quench change-over process while Improving floor space utilization.

- VersaTemp Pyrometer Control Integration: Achieve advanced temperature control with VersaTemp Pyrometer control integration. Ensure accuracy and consistency in your heat-treating operations by allowing one or more pyrometers to interface directly with your system’s power supply.

- Pneumatic Door: Experience convenience and safety with a pneumatically actuated door. Streamline access and workflow while prioritizing operator safety and well-being.

- Footswitch: Optimize hands-free operation with a footswitch. Take control of your heat-treating processes with enhanced convenience and flexibility.

- X/Y Adjustable Table for Heat Station: Tailor your heat station and coil alignment with an X/Y adjustable table. Achieve precise positioning for optimal heating results.